Frequently Asked Questions For Panasonic Programmable Controllers

Panasonic 12th Dec 2022

PWM output specification is specified when carrying out PWM operation of the output Y automatically according to a PID output (MV).

On the other hand, analog output specification stops a PWM output.

PID output instead stored in the head area of the work area for operation (S4-) (MV).

It is used outputting to direct read-out and a process.

PID output instead stored in the head area of the work area for operation (S4-) (MV).

It is used outputting to direct read-out and a process.

If GT11 is connected to the 2ch port of a FP-XCOM6 communication cassette (RS485x2ch type), operation of a switch or a lamp may become slow and it may not operate. A setup of COM2 (2ch port) is a computer link. In addition, in COM1 (1ch port), it operates normally satisfactory. Why is it?

Since the change timing of transmission and reception of RS485 does not suit the cause of generating, it is why communication broke off and carried out, and was and the abnormalities in communication occurred. Moreover, the change methods of transmission and reception differ by 1ch of FP-X COM6 cassette, and 2ch(es). For the reason, a difference occurs in communication.

Please set delay time to both FP-X and GT11 display for indication as a measure.

FP-X: On a program, please execute SYS1 command and lengthen COM2 response time.

GT11: Please set up delay time by COM port communication setup of a display for indication.

FP-X: On a program, please execute SYS1 command and lengthen COM2 response time.

GT11: Please set up delay time by COM port communication setup of a display for indication.

Cautions: Please set it as FP-X:1ms and GT11:5-10ms, and try.

IÃÂâÃÂ?ÃÂ?m using FP0 SL1. When executing the total check on-line, "Duplicated output error" message was indicated. How do I solve this?

The number in "Duplicated output error" message is the program error address number. The OUT instruction written in the address (step) is also used in another step. Therefore, correct the duplicated output. To enable the duplicated output, uncheck the "No.20 Disable settings for duplicated output" box in "PLC Configration" abnormal operation items.

IÃÂâÃÂ?ÃÂ?m planning to use FP-X. At present, there are only five COM port numbers that can be assigned by FPWIN G (1 to 5), and all of them are used by the system. How can I increase the number of COM port assignments? In addition, if the USB port of FP-X is connected, can it be recognized?

Versions of FPWIN GR earlier than Ver. 2.2 can only assign PC port numbers COM1 to COM5. However, Ver. 2.3 or later can assign ports COM1 to COM15.

For FP-X, FPWIN GR Ver. 2.5 or later is used. Therefore, the COM port settings can be changed. Download a file for upgrading to the latest version from our software page.

When FPWIN GR is upgraded to the latest version, the USB driver for FP-X is automatically installed. When you connect the USB port of FP-X with that of your PC using a commercially available USB cable (with the A-male USB connector on the PC end and the B-male USB connector on the FP-X end), FP-X can be automatically recognized, and the COM number is assigned. Go to the menu bar of FPWIN GR > Options > Communication Settings, and change the port number to the assigned COM number to use the unit.

How do I use the Auto_Open operator with a specified BOOK only?

When you do not want to execute the Auto_Open operator when displaying a version history book etc.

Sub Auto_Open()

If the book name is not OpenTest.xls, return immediately.

If ActiveWorkbook.Name <> "OpenTest.xls" Then Exit Sub

If the book name is not OpenTest.xls, return immediately.

If ActiveWorkbook.Name <> "OpenTest.xls" Then Exit Sub

(Execution code)

End Sub

End Sub

How do I use PCWAY to process an automatic monthly report?

In order to use PCWAY to process an automatic monthly report, your system must satisfy the following conditions. If it does not satisfy these conditions, we recommend that you carry out the processing manually (by pressing the buttons in the Excel spreadsheet).

1. The system must be capable of 24-hour operation.

2. PCWAY must be setup for continuous monitoring.

3.The time for the monthly report processing must be established.

The following assumes that you want to perform the monthly report on the 1st day every month. Specify the spreedsheet as "TEST" , and event as "V0".

1. In the spreadsheet "TEST", set the PCWAY cell data setting to set V0 of WRITE mode. In this example, we will allocate the cell data settings to cell A1 (regarding allocation cell position, a cell position that hides the cell as much as possible is best).

2. Input 1 to cell "A1" (input 0 to switch off).

3. Define the following Macro.

Sub Monthly report()

Dim SheetSave As String

Declaration of the save area for the sheet name being displayed

Dim MyDate As Integer

Declaration of the save area for today's date

MyDay = Day(Now())

MyDay represents today's date

If MyDay = 1 Then

Check if it is one day or not

SheetSave = ActiveSheet.Name

Represent the displayed spreadsheet name as SheetSave

Application.ScreenUpdating = False

Stop the Excel display

Sheets("TEST").Select

Switch to TEST

Call Application.Run("PCWAYsubAutoSheet")

Notify PCWAY that the spreadsheet has been switched

Range("A1").Select

Move the cursor to A1

Call Application.Run("PCWAYsubDownLoad")

Set V0 on

Sheets(SheetSave).Select

Return to the original spreadsheet

Application.ScreenUpdating = True

Start the Excel display

End If

End Sub

Start the Excel display

4. Register the monthly report processing macro of step 3. for PCWAY automatic macro launch, and register the trigger device for automatically launching the registered macro as the weekly timer register.

How do I switch PLC contacts during execution of a PLC macro?

To explain this, letÃÂâÃÂ?ÃÂ?s assume that the name of the spreadsheet is "TEST" and that we want to switch bit 0 the PLC internal relay R on.

1. In the spreadsheet "TEST", set the PCWAY cell data setting to set R0 of WRITE mode. In this example, we will allocate the cell data setting to cell A1 (regarding allocation cell position, a cell position that hides the cell as much as possible is best).

2. Input 1 to cell "A1" (input 0 to switch off).

3. Insert the following Macro in the Macro that you want to turn R0 on.

Macro name()

DIM A$ AS String

Declaration of the save area for the sheet name being

ÃÂâÃÂ?ÃÂâ

ÃÂâÃÂ?ÃÂâ

ÃÂâÃÂ?ÃÂâ

ÃÂâÃÂ?ÃÂâ

A$ = ActiveSheet.Name

Represent the sheet name being displayed

Application.

screenUpdating = FALSE

Stop the Excel display

Sheets("TEST").Select

Switch to TEST

Call Application.Run

("PCWAYsubAutoSheet")

Notify PCWAY that the spreadsheet is switched.

Range("A1").Select

Move the cursor to A1

Call Application.Run

("PCWAYsubDownLoad")

Set R0 on

Sheets(A$).Select

Return to the original she

Application.

screenUpdating = FALSE

Stop the Excel display

Sheets("TEST").Select

Switch to TEST

Call Application.Run

("PCWAYsubAutoSheet")

Notify PCWAY that the spreadsheet is switched.

Range("A1").Select

Move the cursor to A1

Call Application.Run

("PCWAYsubDownLoad")

Set R0 on

Sheets(A$).Select

Return to the original she

How do I display cell contents on the top of bitmap graphics etc.?

Select [Format] - [Sheet] - [Background] in the Excel menu.

Here you can select the image file to be used for the background.

When you use this function, the image file is displayed at the back of the cells.

The image is tiled in the same way as with the "Entire Screen" setting in Windows Wallpaper, so some care is required with the size of the image.

The image is tiled in the same way as with the "Entire Screen" setting in Windows Wallpaper, so some care is required with the size of the image.

I have already set up a PLC link with MEWNET-W. Can I connect PCWAY to one of the units and access all stations?

If you connect PCWAY to the port (TOOL port or COM port (only TOOL port for FP10S)) on CPU Unit, it is possible. (Not possible if connected to CCU.) When doing so add a checkmark to ÃÂâÃÂ?ÃÂ?Use Link unit No. when connection by RS232C?, as shown below. By making this setting you will be able to access PLCs existing on the same network. Please use station No. ?0? to access the local station.

How do I display the PLC calendar timer value in "YY/MM/DD" format on the spreadsheet?

This cannot be done unless you create an Excel Macro.

Use the calendar timer in special registers 9054 to 9056 to display the data in the following format on the Excel spreadsheet.

The date is January 13, 1999 and the time is 17:27:29

What does "merging cells" mean?

"Merging cells" refers to using an Excel function to join two cells together (say A1 and B1) in an Excel spreadsheet.

To join cells A1 and B1

1. Click the right mouse button with A1 and B1 selected.

2. Select the Alignment tab in the Format Cells window.

3. Select the "Merge Cells" check box, and click OK.

1. Click the right mouse button with A1 and B1 selected.

2. Select the Alignment tab in the Format Cells window.

3. Select the "Merge Cells" check box, and click OK.

The two cells A1 and B1 are now merged.

Use this to magnify the display. The merged cells can only contain the settings for one cell.

1. Test environment

Windows98

Excel97

PCWAY Ver. 2.102

Excel97

PCWAY Ver. 2.102

2. Functions with no problems

- Changing the contact character

- Register display

- Write processing to the above two

- Download function

- Register display

- Write processing to the above two

- Download function

3. Functions that cannot be used

- Copy and paste of merged cells

- Display of file data

Merged cells are unmerged when file data is displayed.

- Display of file data

Merged cells are unmerged when file data is displayed.

How do I display BCD?

To display and perform an operation in the same cell, use hexadecimal display for the cell data setting. However, in the case that there are fewer than four digits in the BCD display, (fewer than 8 digits for one or two word display), zeros are displayed in front of the other digits.

Example: PLC DT0 23 (HEX display) -> 0023 on the Excel spreadsheet

With the following method, it is possible to eliminate the leading zeros.

Example: PLC DT0 23(HEX display) -> 23 on the Excel spreadsheet

Setting method

1. Assuming 0023 is displays in the cell "A1" actually, you set the formula "VALUE(A1)" in the cell "A2" so that "A2" displays just '23' without '00'.

1. Assuming 0023 is displays in the cell "A1" actually, you set the formula "VALUE(A1)" in the cell "A2" so that "A2" displays just '23' without '00'.

2. Input the following operator into the cell in the Excel spreadsheet where you want to display BCD.

Example: If A1 is the cell position, input: =VALUE(A1)

What happens with PCWAY when the print macro is running, and a printer error (out of paper etc.) occurs?

There is no problem. Printer errors are handled by Windows, and not PCWAY or Excel. PCWAY and Excel will continue operating normally even if a printer error occurs.

Can I organize Excel macros on a book basis?

Yes you can, subject to the following conditions.

1. Open the Macro book at the back of the display book.

2. Use the PCWAY automatic macro start registration to add the book and set the macro names.

2. Use the PCWAY automatic macro start registration to add the book and set the macro names.

Example: If the macro book name is MACROTEST.XLS and the macro name is MACRO01.

Registered macro name: MACROTEST.XLS!MACRO01

Registered macro name: MACROTEST.XLS!MACRO01

If the display book and macro books are divided in this way, the macros for processing the version history book are also saved together, so it is easier to manage the data with Excel books.

When displaying file data, how can I switch rows and columns?

At the moment, the only way to do this is to first display the file data in a sheet, and then execute a macro on this data that switches rows and columns. Use "Register Auto Macro Launch" to set the macro to launch on, for example, a notification event set using "Register File Process",

1. Copy the macro of the blue part below into the module of the book that you are using. There is no need to edit it.

2. Operation methods of the macro below.

Example 1:

Switch the rows and columns in the range B2:D5 in Sheet 1, and paste them starting from B2 in Sheet2.

Call Application.Run("RowColumn_Change", "Sheet1", "B2:D5", "Sheet2", "B2")

Switch the rows and columns in the range B2:D5 in Sheet 1, and paste them starting from B2 in Sheet2.

Call Application.Run("RowColumn_Change", "Sheet1", "B2:D5", "Sheet2", "B2")

Example 2:

Switch the rows and columns in the range B2:D5 in the active sheet, and paste them starting from cell B7 in the active sheet.

Call Application.Run("RowColumn_Change", "", "B2:D5", "", "B7")

Note: this will not work if any of the destination cell positions are inside the range of the source cells.

Switch the rows and columns in the range B2:D5 in the active sheet, and paste them starting from cell B7 in the active sheet.

Call Application.Run("RowColumn_Change", "", "B2:D5", "", "B7")

Note: this will not work if any of the destination cell positions are inside the range of the source cells.

Example:

Switch the rows and columns of the file data is displayed in the range B2:D5 in Sheet1, and display from B7 in Sheet2.

Switch the rows and columns of the file data is displayed in the range B2:D5 in Sheet1, and display from B7 in Sheet2.

1) Copy the macro in the blue part below into the module of the book that you are using.

2) Create a macro.

Sub test()

'When copying between different sheets, the following three lines are required because the data in Sheet1 is not updated when Sheet2 becomes active. 'This macro "PCWAYsubSheetRefreshNoMessage" can only be used with Ver1.06 and later.

Sub test()

'When copying between different sheets, the following three lines are required because the data in Sheet1 is not updated when Sheet2 becomes active. 'This macro "PCWAYsubSheetRefreshNoMessage" can only be used with Ver1.06 and later.

If ActiveSheet.Name <> "Sheet1" Then

Call Application.Run("PCWAYsubSheetRefreshNoMessage", "Sheet1")

End If

Call Application.Run("PCWAYsubSheetRefreshNoMessage", "Sheet1")

End If

Call Application.Run("PCWAYsubRowColumnChange", "Sheet1", "B2:D5", "Sheet2", "B7")

End Sub

End Sub

3) Select the process checkbox of the "Register File Process" notification event, and register V0 as the event.

4) Select the "Register Auto Macro Launch" process checkbox, and register the trigger as V0, and the macro name as test.

End. Row to column switch process

--------------------------------------------------------

Parameter1 strFromSheet : Name of the source sheet. If "", it is the active sheet. Ex) "Sheet1"

Parameter2 strFromRange : Source switch range Ex) "B2:D10"

Parameter3 strToSheet : Name of the destination sheet. If "", it is the active sheet. Ex) "Sheet2"

Parameter4 strToCell : Start cell position in the destination sheet Ex) "B2"

Parameter2 strFromRange : Source switch range Ex) "B2:D10"

Parameter3 strToSheet : Name of the destination sheet. If "", it is the active sheet. Ex) "Sheet2"

Parameter4 strToCell : Start cell position in the destination sheet Ex) "B2"

Operation example 1:

Switch the rows and columns of the range B2:D5 in Sheet1, and paste from cell B2 in Sheet2

Call Application.Run("RowColumn_Change", "Sheet1", "B2:D5", "Sheet2", "B2")

Call Application.Run("RowColumn_Change", "Sheet1", "B2:D5", "Sheet2", "B2")

Operation example 2:

Switch the rows and columns of the range B2:D5 in the active sheet, and paste from cell B7 in the active sheet

Switch the rows and columns of the range B2:D5 in the active sheet, and paste from cell B7 in the active sheet

Call Application.Run("RowColumn_Change", "", "B2:D5", "", "B7")

Note: this will not work if any of the destination cell positions are inside the range of the source cells.

-----------------------------------------------------------

Sub PCWAYsubRowColumnChange(strFromSheet As String, strFromRange As

String, strToSheet As String, strToCell As String)

Dim strSheetname As String

If strFromSheet = "" Then

strSheetname = ActiveSheet.Name

Else

strSheetname = strFromSheet

End If

String, strToSheet As String, strToCell As String)

Dim strSheetname As String

If strFromSheet = "" Then

strSheetname = ActiveSheet.Name

Else

strSheetname = strFromSheet

End If

Worksheets(strSheetname).Range(strFromRange).Copy

If strToSheet = "" Then

strSheetname = ActiveSheet.Name

Else

strSheetname = strToSheet

End If

If strToSheet = "" Then

strSheetname = ActiveSheet.Name

Else

strSheetname = strToSheet

End If

Worksheets(strSheetname).Range(strToCell).PasteSpecial

Paste:=xlFormats, Operation:=xlNone, SkipBlanks _ :=False, Transpose:=True Worksheets(strSheetname).Range(strToCell).PasteSpecial Paste:=xlValues, Operation:=xlNone, SkipBlanks _ :=False, Transpose:=True

Application.CutCopyMode = False

End Sub

Paste:=xlFormats, Operation:=xlNone, SkipBlanks _ :=False, Transpose:=True Worksheets(strSheetname).Range(strToCell).PasteSpecial Paste:=xlValues, Operation:=xlNone, SkipBlanks _ :=False, Transpose:=True

Application.CutCopyMode = False

End Sub

When displaying the value in one cell in another cell, how do you display a blank as blank?

If, for example, you want to display the value in cell A1 in the cell B1, and set the formula in cell B1 to =A1, when the value in A1 is blank, "0" is displayed in cell B1.

To get around this, set the formula in B1 to =IF(ISBLANK(A1),"",A1).

This formula displays "" in B1 if cell A1 is blank, and the value in A1 if cell A1 is not blank.

When using PCWAY, the PC's clock data goes askew.

If PCWAY is launched while running virus scanning software, the clock will go askew, running faster.

The extent depends on the PC used, but if you frequently perform PCWAY file processing, in particular, the clock will delay about 10 seconds over a ten minute span.

When attempting to start up PCWAY, the message "Security unit not installed" is displayed and PCWAY does not start up.

An NEC PC9821 Series PC was used.

Since the serial port on this PC has a D-Sub 25 pin, installation may sometimes be incorrect. Unfortunately, the NEC PC9821 Series is not supported by PCWAY Ver. 2.3 and higher.

How do I display the contents of two registers in one cell?

To display the contents of, say, DT0 and DT1 in one cell, refer to the example given below.

*Example:

To display the PLC's hours and minutes, use a program to transfer the contents of DT9053 (hours/minutes) to DT0 and DT1.

Output deviates when the system register is initialized.

When there is a model change when using FPWIN GR, the content of the system register will be initialized and the I/O allocation is also initialized.

Although in the original I/O allocation setting, MEWNET-H was set to "0SE", it became "16SE" by being initialized when the model was changed.

This caused the addresses to shift one word back for all subsequent units.

This caused the addresses to shift one word back for all subsequent units.

"MEWNET manager run error" occurs and FPWIN GR does not launch after the OS on the PC is upgraded.

This phenomenon occurs when the OS is upgraded to Windows NT, Windows 2000 or Windows XP from Windows 9X onto which FPWIN GR was originally installed. This is because, in order to promote stability of applications, the folder/path that system files related to communications are stored are different for Win9X-lineage systems and WinNT-lineage systems.

If this phenomenon occurs, uninstall FPWIN GR and then reinstall it.

Communication works with the SDU connected to an external device (PC), but stops working after a different PC is connected to the CPU tool port and then removed. Later, when a different PC is connected to the tool port, the SDU is able to communicate, but it becomes unable to communicate when the tool port and the different PC are disconnected.

The pin layout on the RS232 cable is wired incorrectly.

For example, a straight cable is being used.

SDU device (PC)

2(SD) 2(RD)

3(RD) 3(SD)

5(CS) 4(GND)

7(GND) 7(RS)

2(SD) 2(RD)

3(RD) 3(SD)

5(CS) 4(GND)

7(GND) 7(RS)

With this wiring, communication is not normally possible because the GND of the SDU and the GND of the external device (PC) are not connected. However, if both the SDU and the GND of the external device (PC) have a similar potential, communication may be possible.

By removing and inserting the cable of a separate device in one of the ports of the PLC, the potential on the PLC side will change and communication will become disabled.

The solution is to rewire the connections correctly.

When I connect a Serial data unit (SDU here after) to an external device (PC) and attempt to communicate, the SDU can communicate when the PC is connected to the CPU tool port, but when the PC is disconnected, the SDU is not able to communicate.

The pin layout on the RS232 cable is wired incorrectly.

For example, a straight cable is being used.

SDU External device (PC)

2(SD) 2(RD)

3(RD) 3(SD)

5(CS) 5(GND)

7(GND) 7(RS)

2(SD) 2(RD)

3(RD) 3(SD)

5(CS) 5(GND)

7(GND) 7(RS)

With this wiring, communication is not possible because the GND of the SDU and the GND of the external device (PC) are not connected. However, by connecting a different PC to the CPU tool port, the GND in the PLC and FG become shared through the PC COM port connected to the tool port. Furthermore, since the SG of the PC connected to the SDU is connected to the FG in the PLC through that PC's FG, the FG of the communication cable and the FG of the SDU, it becomes shared with the SG in the PLC. As a result, communication becomes possible. The solution is to rewire the connections correctly.

Error 26 occurs when transmitting a MEWTOCOL command with station number 00 from a PC.

Valid, usable MEWTOCOL station numbers are EE or 01 to 64. If transmission is performed with any other station number, the station number setting error, error 26, is returned.

Overwrites cannot be performed during execution.

Although pixel writing during execution is possible on models with suffixes B or C in the part number, this is not possible on other models (because they are early versions, the suffix is A or a numeral).

Boolean ladder writing during execution is possible with all CPUs.

How to create two or more different systems?

1) Use Windows Explorer to create a working folder for the 2nd system

Example: Create the folder Testno2.

2) There is already a PLC folder in the folder that PCWAY was installed in, so copy all of the files in the PLC folder into the folder that you created in step(1).

3) Open the PCWAY operating environment settings, and change the working folder to the folder that you created in step (2).

Example: Change the setting to the Testno2 folder.

Example: Change the setting to the Testno2 folder.

4) All of the registered data is in the initiallized state, so perform the settings for the new system.

How do I temporarily turn off PCWAY in EXCEL?

When you install PCWAY, the PCWAY icons and menu items appear in Excel. If these get in the way when you are not using PCWAY, it is possible to temporarily turn them off and return to the original settings.

Method:

1) Select [Tools] - [Add-Ins] from the Excel menu bar.

2) Uncheck PCWAY in the Add-Ins window.

1) Select [Tools] - [Add-Ins] from the Excel menu bar.

2) Uncheck PCWAY in the Add-Ins window.

3) Restart Excel. The items related to PCWAY will not be displayed.

When the target speed only is raised at the same target position, it moves 3 times more than it should.

When normal When abnormal

Startup speed 100 100

Target speed 1000 1000

Deceleration time 10 10

Target value 325 325

Move result 325 975

With a user program, the E point startup signal turned on at 100 msec, but with the data on the right hand side, above, one movement finished in 44 msec. Since the startup signal was still on even after the movement was finished, further movement occurred.

Even though I carried out remote programming using W2 mode on the FP2 Multi-wire link unit, the "W2" item does not show up as a choice for network communication station setting.

The communication station setting appear on screen following the pattern shown below: on the 3rd to 5th level down, the "MEWNET" of "Route * (MEWNET/ET-LAN)" stands for MEWNET-P/ MEWNET-W/ MEWNET-W2.

Operation is fine when using only a master backplane, but when an expansion backplane is connected the LEDs of the power supply unit and CPU unit on both the master and expansion sides turn off.

This type of phenomenon occurs when power is not correctly supplied to the power supply unit on the expansion side. Also, this type of phenomenon occurs when the unit's total current consumption (5V) on the expansion side exceeds the capacity of the power supply unit on the expansion side.

What is the operating environment for FPWIN GR?

OS | Windows 95/98/NT (Ver. 4.0 or later)/2000/XP Home/XP Pro

Required hard disk capacity | 30MB or more

Recommended CPU | 100MHz Pentium or faster

Recommended installed memory | 32MB or more

Recommended monitor | 800 x 600 pixels or more

Recommended color | High Color(16-bit) or higher

The power turned on, but the LEDs of the power supply unit and the CPU did not illuminate.

This type of phenomenon occurs when the unit's total current consumption (5V) exceeds the capacity of the power supply unit.

Are there any functions present in NPST-GR but not FPWIN GR?

Refer to the following list

- The Merge Registration and loading functions.

Use the Copy and Paste functions in Windows.

- Verifications cannot be carried out targeting files.

The file to be verified must first be loaded, and then verified.

Use the Copy and Paste functions in Windows.

- Verifications cannot be carried out targeting files.

The file to be verified must first be loaded, and then verified.

The internal relay turns itself on when the power is turned off and on.

When a battery is not installed, this phenomenon occurs when system register No. 7 (start number of the internal relay holding area) is set to a value lower than the initial value 90. Use in this way causes an attempt to back up internal relay R using the battery, but since the battery is not installed the status of the area set for holding is not definite. The same thing can be said for the timer counter elapsed value of system register No. 6 and the value of data register No.8.

If a battery is not installed, please leave this setting at the initial value. (Areas subsequent to the area set with the initial value are backed up in the EEP-ROM area, so there is no possibility of values becoming indeterminate.)

Can NPST-GR read files created using FPWIN GR?

To enable a program created using FPWIN-GR to be read by NPST-GR, export it using the Export function. However, the comments cannot be read.

*Reference information

If programs and comments created using FPWIN GR are downloaded to a PLC with comment memory, it is not possible for NPST-GR to read out the comments. It can, however, read the program.

If programs and comments created using FPWIN GR are downloaded to a PLC with comment memory, it is not possible for NPST-GR to read out the comments. It can, however, read the program.

Can FPWIN GR read files created using NPST-GR?

It can read files created with NPST-GR Ver. 3 or Ver. 4 (including I/O comments, Remarks, and Block comments).

If operation is stopped by the JOB stop signal during positioning operation (JOG operation), does operation decelerate to a stop or stop immediately?

It decelerates to a stop according to the acceleration/deceleration of positioning data.

Is it possible to return to the home position using just the home position sensor?

Yes. By setting bit 5 of the control code to on, you can make it as though the near home sensor was on from the outset. If you perform a return to near home in this state, the operation will take place a low speed.

I set the parameters and data, but the next day they were gone (E Type). Why?

In the case of the E Type, you have to write the settings to the EEPROM. Write the data using "Expansion" + "0" with the Teaching Unit, or use a program to write the data.

What are the benefits of using data No. 401 to 410 of the Positioning Unit (F Type)?

If there are 10 or fewer items of positioning data, using No. 401 to 410 allows you to avoid having to perform a write transfer. This affords the following benefits:

- Faster response time when you want to perform immediate positioning using data loaded from the outside.

- Shorter programs because there is no need for a write transfer program.

- Shorter programs because there is no need for a write transfer program.

Is JOG operation possible when an overrun switch has been on?

Yes. However, movement is either clockwise or counter-clockwise.

Does pulse output stop when an overrun switch is on during JOG operation?

Yes.

When an overrun switch has been on, is it possible to return to origin and to start a job?

Operation is not possible until the overrun switch is released (although in JOG mode, operation is possible even when the overrun switch is on).

Driver faults occur even though there is no servo driver fault occurring.

Reverse settings of Interface logic bit 2 in the parameter

A Limit over error occurs even though the limit switch has not been on.

Reverse settings of Interface logic bit 5 in the parameter

A photocoupler is used in the home position input circuit of FP2 positioning unit and there is also one with a driver output in the Z phase signal output of the servo driver.

Can direct connection be made here?

Two impedances, 220 O (560O) and 1.6 KO (3.0 KO), are available for the home position input of the FP2 positioning unit and each has its own terminal. When connecting a line driver, please connect it to the 220 O (560O) terminal.

Note: The impedance value in brackets is for the multi-function type.

Can I use control codes to change the logic for X6 (home position input ) and X7 (home position near home input)?

Yes, you can. D LED (near home input) and Z LED (home position input) on the front side of unit will change. The control codes can be set at E point control time and also during JOG operation except for return to home position. In this case, however, if you carry out programming but do not change bit 4 and bit5, the logic for X6 (home position input) and X7 (home position near home input) will not change.

Example:

Other than programs can I store data registers and other items in ROM?

Yes, this is possible.

In FPWIN GR, when ÃÂâÃÂ?ÃÂ?ROM <- RAM? under ÃÂâÃÂ?ÃÂ?ROM & RAM Service? is selected and you click the ÃÂâÃÂ?ÃÂ?Data? button, the ÃÂâÃÂ?ÃÂ?Data register range setting? screen appears. Here, you can set the content that you want to put into ROM.

Does the FP2 have a trace function?

A1.In order to use the trace, you will need to install a Memory Expansion Unit on one of the types that allow RAM expansion. - With comment, calendar and expansion RAM: FP2-EM2 - With comment, calendar, ROM socket and expansion RAM: FP2-EM3 - With ROM socket and expansion RAM: FP2-EM6

A2. The trace function can be used as standard on the FP2SH.

Does the I/O unit have a connector attached?

DC Input Unit FP2-X32D2(AFP23064)

FP2-X64D2(AFP23067)

Transistor Output Unit FP2-Y32T(AFP23404)

FP2-Y32P(AFP23504)

FP2-Y64T(AFP23407)

FP2-Y64P(AFP23507)

Mixed I/O Unit FP2-XY64D2T(AFP23467)

FP2-XY64D2P(AFP23567)

Mixed I/O Unit with ON pulse catch inputs FP2-XY64D7T(AFP23477)

FP2-XY64D7P(AFP23577)

CPU Unit with 64 inputs FP2-C1D(AFP2212)

High-speed Counter Unit FP2-HSCT(AFP2441)

Pulse I/O Unit FP2-PXYT(AFP2442)

Positioning Unit (2 axes) FP2-PP2(AFP2430)

Positioning Unit (4 axes) FP2-PP4(AFP2431)

Positioning Unit (Multi-function, 2 axes, transistor) FP2-PP21(AFP2432)

Positioning Unit (Multi-function, 4 axes, transistor) FP2-PP41(AFP2433)

Positioning Unit (Multi-function, 2 axes, line drive) FP2-PP22(AFP2434)

Positioning Unit (Multi-function, 4 axes, line drive) FP2-PP42(AFP2435)

Are common pins with the same names in MIL type input connectors and output connectors connected internally?

Yes, they are connected internally. (They are not connected across control units and expansion units)

F168 (SPD1) instruction/ Is it possible to return to home position using only the home position sensor without using the near home sensor?

Yes, it is possible. By specifying H20, H22 or H23 when selecting the control code operation mode, the pulse is stopped once the home position sensor is turned on with no relation to the near home sensor.

F168 (SPD1) instruction/ Will deceleration start when the near home sensor turns on during acceleration when home position return is taking place?

Yes, deceleration starts even if acceleration is occurring.

F168 (SPD1) instruction/ Will the home position return operation complete even immediately after the near home sensor is input when the home position return mode is set to H24, H26 or H27 (home position input valid after near home input)?

After near home sensor input, the home position sensor becomes valid after deceleration is complete.

F168 (SPD1) instruction/ Does FP0 start pulse output when home returning is execated under the home position sensor has been turned on?

For the F168 instruction there are six operation modes for returning to home position: H20, H22, H23, H24, H26, and H27. Pulse output is started in any of these modes when F168 instruction is executed even if the home position sensor is turned on.

The lengthy error or syntax error is displayed when a compare instruction of a basic instruction is written.

-When written during execution:

-When written during execution:

The CPU version determines what can and cannot be written.

FP-e All versions okay

FP0 All versions okay

FP Sigma All versions okay

FP1 (C20 and above) Okay from Ver. 2.7

FP-M (C20 and above) Okay from Ver. 2.7

FP2 All versions okay

FP2SH All versions okay

FP3 Okay from Ver. 4.4

FP10SH All versions okay

FP0 All versions okay

FP Sigma All versions okay

FP1 (C20 and above) Okay from Ver. 2.7

FP-M (C20 and above) Okay from Ver. 2.7

FP2 All versions okay

FP2SH All versions okay

FP3 Okay from Ver. 4.4

FP10SH All versions okay

-Perform the following change if using a control unit for which writing is not possible.

F168 (SPD1) instruction

Can outputs Y2 and Y3 be used for another purpose when "Do not use directional output." is set ?

Can outputs Y2 and Y3 be used for another purpose when "Do not use directional output." is set ?

Yes, You can use them without any concern for F168 instruction.

A syntax error occurs after executing a program written to change the calendar timer area (DT9054, etc.) with the F6 (digit transfer) instruction.

The only instruction that can be used to change the calendar timer area of a special data register is the F0 (transfer) instruction.

I downloaded a new program to the PLC and ran it, but after turning on the power, the count instruction counted up and normal control was not possible.

Since the counter instruction is normally set for holding, the elapsed value is stored during a power failure. The elapsed value status is held even if the power is turned off. Later, since the holding area content does not change even if a new program is downloaded, the elapsed value status will obviously not have changed.

In such a case, connect an R9013 (initial relay) to the counter instruction reset input and reset the elapsed value when turning on the power.

F168 (SPD1) instruction

How long does it take to output the pulse after the directional signal turns on?

100 ? sec.

The FP0 COM port has only three pins. How do I connect it to another piece of equipment?

*In the case of the Matsushita Electric Works, Ltd. Programmable display GT10

*In the case of the Digital Inc. GP series display panel

I am reading digital switches, and on occasion, when the digit is converted, operation errors occur. Upon investigation, it seems that the error is occurring in the location of the BIN Conversion instruction.

The frequency that this problem occurs depends on the manufacturer of the digital switch and the type. The problem occurs when a value other than 0 to 9 is input at the instant that a value is switched, and this causes the operation error with the BIN Conversion instruction.

Simple ways of preventing this operation error are given below.

Example 1: In the case that one digit of the digital switch is connected to X10 to X13.

Example 2: In the case that two digits of the digital switch are connected to X10 to X17.

Example 3: In the case that four digits of the digital switch are connected to X10 to X1F.

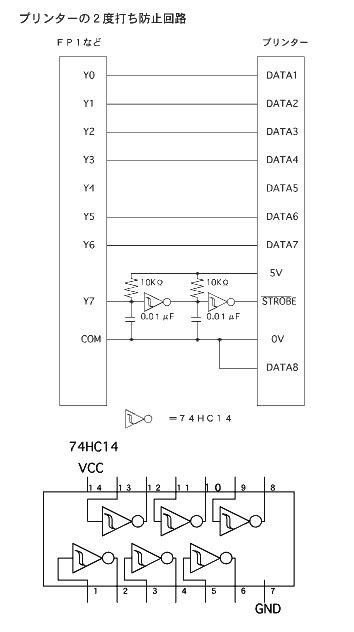

When I print using F147 (printout instruction), sometimes I end up with two printouts.

With the FP Series, it is possible to directly connect to the Centronics port on the printer. Although rare, some printers (particularly compact models) are not equipped with an anti-chatter circuit (Schmitt trigger). In such cases, connect an external circuit like the one shown on the following page to prevent double printouts.

Is it possible to use PLC Link while carrying out general-purpose communications (FPG-COM4)?

It is possible by using RS485 1channel and RS232C 1channel type communication cassette(FPG-COM4). Use CH2 for general-purpose communication and use CH1 for PLC Link. (In this case the limit on number of stations is 5 and the transfer distance becomes 100 m (total extension).) The following is a configuration diagram and setting example.

*Configuration diagram

- Station No. 1 setting

- Station No.2 setting

- Station No.5 setting

The error is not cleared even though clicking "Error clear" in the status screen.

If the error is cleared while the cause of the error has not been removed when the mode switch is set to RUN, the error will re-occur if the program is executed immediately after clearing the error. At this time the error is momentarily cleared, but the error LED continues to illuminate (flashed depending on the model), so it appears that the error has not been cleared.

In such a case, please perform the error clear in either REMOTE mode or PROG mode.

What is the allocation when using a remote I/O?

The allocation of the FP0 I/O link unit on the FP0 side differs depending on the expansion position. The variations are shown below.

*configuration

- When the first FP0 expansion unit is an I/O link unit:

- When second and third FP0 expansion units are I/O link units:

Is it necessary to designate separate station numbers for the MEWTOCOL stations when two CCU ports are used or when multiple CCUs are being used simultaneously?

The MEWTOCOL station numbers when using CCUs can be any number as long as they are in the range between 1 and 64. The same station number can even be used at the same time.

Is there an 8-bit-only transmission instruction?

There are no 8-bit transmission instructions.

Please use the F6 (digit transfer) instruction.

Example 1)

|---||---[ F6(DGT), HFF, H10 , WY18 ]

Explanation: HFF is transferred to Y180 to Y187.

|---||---[ F6(DGT), HFF, H10 , WY18 ]

Explanation: HFF is transferred to Y180 to Y187.

Example 2)

|---||---[ F6(DGT), HFF, H210 , WY18 ]

Explanation: HFF is transferred to Y188 to Y18F.

|---||---[ F6(DGT), HFF, H210 , WY18 ]

Explanation: HFF is transferred to Y188 to Y18F.

Can Data Register (DT) be used for a timer instruction setting?

Data Register (DT) can only be used in the setting for the two models, FP2SH and FP10SH. Although DT cannot be used in other models, timer/counter set value area (SV) can be used. Please use SV in place of DT.

If a contact identical to the MC instruction trigger (execution condition) begins from the mother line inside MC-MCE and a DF instruction exists immediately to the right, that contact won't be able to be differentiated even if the trigger (execution condition) turns on.

The DF instruction detects a rise when the previous OFF execution result is stored and the current execution result is ON. (The opposite applies for DF/.) In this program, although the DF instruction inside MC-MCE does not execute when the MC instruction execution conditions are first established after running, since there is no ON/OFF information from the previous execution, R100 does not turn ON because the rise cannot be detected.

Also, even when there are two or more subsequent MC instruction executions, if RO was on during the last scan when the previous MC instruction was executed, R100 will not turn on because the rise cannot be detected.

However, for only the FP2, FP2SH and FP10SH, detection will always occur when the checkmark in the item below is removed in the system register settings.

Also, even when there are two or more subsequent MC instruction executions, if RO was on during the last scan when the previous MC instruction was executed, R100 will not turn on because the rise cannot be detected.

However, for only the FP2, FP2SH and FP10SH, detection will always occur when the checkmark in the item below is removed in the system register settings.

Is a battery required when performing ROM operation?

It is possible to operate even without using a battery, but the DT contents, on/off status of R and counter elapsed value that are all designated in the holding area will become indefinite when the power turns on. To preserve the status of these items after the power is turned off please use a battery.

When output COMMONs are together is it possible to connect voltages of differing loads?

It is possible by connecting the minus terminals of each power supply together in case of NPN output type.

Although the system register was set, the setting is not valid. What is wrong?

The settings will be valid from the first time you switch to RUN mode.

In the ROM used for ROM operation, is anything else contained besides the program?

Depending on the content of the system register, password, and product type, items such as DT and FL are contained in the memory aside from the program.

Is there PLC type for writing the contents of DT and FL to ROM?

This is possible with the FP2, FP2SH, and FP10SH.

As with a program, when using this function the ROM content is transferred to RAM (DT and FL area) when RUN mode is first entered after the power is turned on.

A manual alternate circuit is run, but on and off is not stable.

Chattering caused by the input (X0) is the cause.

The faster the CPU the more likely the effect of chattering. Chattering can be absorbed by using a timer instruction as shown below.![]()

The faster the CPU the more likely the effect of chattering. Chattering can be absorbed by using a timer instruction as shown below.

Are there any program examples for CRC for communications with a temperature controller?

Download the following the sample programs from our software page:

ÃÂâÃÂ?ÃÂ?FP? - KT Series Temperature Controller current temperature (PV value) reading (RTU mode)ÃÂâÃÂ?ÃÂÃÂ

ÃÂâÃÂ?ÃÂ?FP? - KT Series Temperature Controller set temperature (SV) writing (RTU mode)ÃÂâÃÂ?ÃÂÃÂ

How do I get the Chinese manuals for FP0 and FPWIN GR?

Unfortunately, the Chinese manuals for FP0 and FPWIN GR are not available in Japan. They may be available in Shanghai. You can check the Panasonic China website.

The English manuals are available in PDF format.

When I use F147 (printout instruction), the data is sometimes printed out twice. How do I prevent this?

FP series can be directly connected to the Centronics interface of a printer.

When connecting the unit to a general printer, there is no possibility of double printouts. However, some printers (compact type in particular) donÃÂâÃÂ?ÃÂ?t have a Schmitt circuit (chattering prevention circuit). In such cases, you can avoid double printouts by installing an external circuit, as shown below.

Although I used colored text for comments, they are printed in black and white even by a color printer. Are any settings required?

FPWIN GR Ver. 2.3 and later support color printing. If you are using an older version of FPWIN GR, download the difference file for upgrade from the following URL and install it.

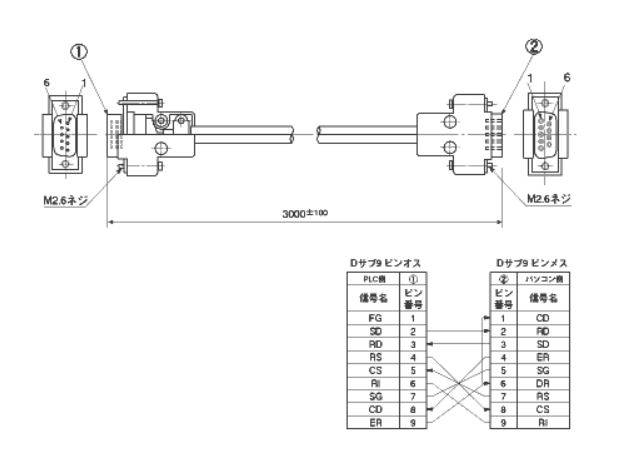

How do I connect the FP2 SDU to the serial port (9-pin type) of a DOS-V computer? The manual only describes the connection with a 25-pin type.

Use the AFB85853 connection cable. Refer to the following wiring diagram:

I need to move a tool in an S-shape by controlling two axes using FPG-C32T and FP0-E32T. How do I program them? I donÃÂâÃÂ?ÃÂ?t know how to program well.

Use F176 circular interpolation pulse output instruction to easily program the S-shaped positioning control. Please refer to FP Series Programming Manual.

Recent notebook computers donÃÂâÃÂ?ÃÂ?t have serial ports, but have USB ports only. How do I connect PLCs, such as FP0, FP1, and FP10SH to edit the programs?

You can use a commercially available RS232C-USB conversion cable.

I installed PCWAY Ver. 2.4 in Windows XP. However, the key unit for the printer port cannot be recognized. What should I do?

It is possible that the key unit control driver cannot be recognized on Windows XP. In such cases, you need to upgrade the driver. The difference file for the key unit driver Ver. 4.96 shared by PCWAY and COMMX is available. The file is called keyunit_spv496.zip.

How are I/O points allocated to expansion units added on the left side? If they are also added on the right side, will the I/O numbers change?

The I/O allocations of the left-side expansion units are as follows:

1st unit: X100 to X11F, Y100 to Y11F

2nd unit: X180 to X19F, Y180 to Y19F

3rd unit: X260 to X27F, Y260 to Y27F

4th unit: X340 to X35F, Y340 to Y35F

The I/O allocation numbers are fixed regardless of presence or absence of the right-side expansion units.

I need to expand the file register (FL) and use the comment memory. Which hardware is required?

IC card board (AFP6209A) and S-RAM card (AIC31000) are required. The IC card board has a 512-KB built-in memory for storing comments. When the IC card DOS size to 512 KB, the rest (512 KB) can be used as an expansion area.

AIC31000 is BN-01MHSRC made by Matsushita Battery industrial Co.,Ltd.

Is there a FP10SH hardware manual?

Visit our documents page to download the manual.

How do I connect the power line of FP0?

The power line connector is a Molex white connector. Use the connector with a cable (1 m) that comes with the unit for connection. Brown: +, Blue: -, Green: FG

Is it possible to set the internal relays of FP1-C14 to the data hold type?

Relays from R100 to R15F are set to the data hold type by default. If you need to set all relays to the data hold type, change the starting word number of the internal relay data hold area to ÃÂâÃÂ?ÃÂ?0ÃÂâÃÂ?ÃÂÃÂ, and write it in "PLC Configuration". The memory of this PLC is backed up by a built-in large-capacity capacitor for 10 days. Note that if the power failure continues for more than 10 days, the data cannot be held.

When using X0 to X4 as a high-speed counter, whatÃÂâÃÂ?ÃÂ?s the maximum counting frequency? And how do I set it? (I wonÃÂâÃÂ?ÃÂ?t use the pulse output function.)

If you donÃÂâÃÂ?ÃÂ?t use the pulse output function, limit the total of the counting frequencies inputted to the counter channels within 10 kHz. You donÃÂâÃÂ?ÃÂ?t have to preset the frequency. If the total exceeds 10 kHz, correct counting will be impossible.

How do I read and write data memory of FP0 in a batch?

Use "Data Editor" included in FPWIN GR. To activate it, go to Windows Start > All Programs > Panasonic MEW Control > FPWIN GR2, and click on "Data Editor". Select "Edit Data Register" and execute uploading from the PLC. With these procedures, you can read, save, and write data in any area you like.

I asked a trading company to estimate AFC13012 and AFC22342C, and the numbers in its reply included ÃÂâÃÂ?ÃÂ?-FÃÂâÃÂ?ÃÂÃÂ. WhatÃÂâÃÂ?ÃÂ?s the difference?

Previously, the part numbers were classified by the presence/absence of the CE marking. At present, all products have the CE marking. Therefore, all part numbers have ÃÂâÃÂ?ÃÂ?-FÃÂâÃÂ?ÃÂÃÂ. Please rest assured that there is no difference in the performance.

X and Y can be directly entered by using the X key and Y key on the keyboard. Can I enter WX and WY in the same manner?

You can enter WX and WY using the U and I keys respectively. For details, refer to the Operand Allocated Key List in "Shortcut keys for Operands" of Help.

Since FP0-T32CT had been powered off for a long time, the data in the data registers was invalidated.

The necessary tool is not locally available. How do I obtain a tool that has the same functions as "Data Editor"?

Download the trial version of FPWIN GR from the software section of our website. Since there are no limitations with "Data Editor" included in the trial version, you can use all of its features as you would with the full version.

Since the program space becomes insufficient, I need to change the CPU unit. If I change FP2 to FP2SH, can the other units be used as they are?

Their memory units and ROMs are not compatible. But the other units can be used as they are. The programs are also compatible.

When rewriting the program, all data in the data area are reset to zero. Therefore, I tried to hold the data by using "Hold PLC Device Value" function of GT10. However, the data still became zero. How can I successfully hold the data?

First of all, "Hold PLC Device Value" function of GT10 is intended to hold data in case of a power failure, and cannot be used for holding the data area. If you need to save the data in a specific area, use "Data Editor", which is software supplied with FPWIN GR. Go to Start of Windows > All Programs > Panasonic MEW Control > FPWIN GR2, and activate "Data Editor". With this software, you can easily read, save, and write any data area of PLC, including an IC card.

The computer I purchased has only USB ports. Since I need to program the sequencer using FPWIN GR, is it possible to connect it via a USB port?

Communications are possible by using a commercially available USB-RS232C conversion cable or adapter.

Make sure to check the new COM port number that will be assigned by the computer for the USB when the USB-RS232C conversion device is registered.

You can check the number in Windows 98/Me by going to Start > Control Panel > System > Device Manager > Ports.

For Windows XP, go to Start > Control Panel > System > Hardware > Device Manager > Ports.

Then, if the assigned port number is COM4 for example, activate FPWIN GR, go to Options in the menu bar > Option > Communication Settings, and change the port number to COM4 to enable the communications.

How do I adjust the response time of communications between FP? and a computer via RS485?

With the SYS1 instruction, you can set the response time of the COM port within the range from 0 to 999 ?sec.

Can an expansion I/O unit be connected to FP0 SL1?

Up to three units can be connected.

The RUN and ERROR LEDs of FP3 are lit.

There is a self-diagnosis error. Connect a programming tool, such as FPWIN GR, Status Display to check the details of the error, and take corrective actions.

How do I write programs in the FP-M master memory (EEP-ROM)?

Power off the unit, install the master memory in the FP-M unit, and set the memory selector switch to EEP-ROM.

Then, make sure to power on the unit in PROG mode. (If you power on in RUN mode, the program will be automatically written to RAM from ROM, overwriting the program you wrote.)

Then, execute the RAM -> ROM transfer(ROM&RAM Survice) using a programming tool, such as FPWIN GR.

IÃÂâÃÂ?ÃÂ?m using four interruption input points of the FP2 high-speed counter unit. How does the unit operate when multiple interruption instructions are executed simultaneously?

The unit executes instructions one at a time in ascending order of interruption program number (INT No.). Therefore, they are not executed simultaneously.

Since an electric leakage is caused, IÃÂâÃÂ?ÃÂ?m planning to measure the insulation resistance between the FP0 power supply and FG using a 500-V megger for investigation purposes. Will there be any problems?

There will be problems. Since there are varistors (39 V) between the power supply (-) and FG, and between the power supply (+) and FG, they will break.

For the same reason, if the voltage between the power line and the ground is excessively high, the varistors may be short-circuited when FG is grounded.

If CH0 and CH2 of FP? are programmed for positioning so that only one of the channels outputs pulses at a time, is it possible to achieve a 100kHz output frequency?

Yes, a 100kHz output frequency can be achieved if either CH0 or CH2 outputs pulses at the same time. If they simultaneously output pulses, the frequency is 60kHz at the maximum.

Can the cable supplied with FPWIN GR (AFC8503) be used for FP1?

No, it canÃÂâÃÂ?ÃÂ?t be used. You need a dedicated cable (AFP15205 or AFP1523), the conversion adapter (AFP8550), and a commercially available RS232C straight cable.

I need to have the FP2 positioning unit multifunction type perform home position return, but there are not near-home position switches. How do I set it if there are only limit switches on both ends and a home position switch?

There are three ways.

(1) Set bit 5 of the control code to 1 so that the near-home position logic will be enabled without current passing through. In this setting, the object moves at the startup speed and stops at its home position. However, if the object is in a position beyond the home position, it moves to the limit switch, stops, and then an error occurs.

(2) This method uses the difference between positions where the input signal of the home position dog is turned ON and OFF. Connect the home position switch in parallel with the home position input and the near-home position input first. Set bit 4 of the control code to 0 (home position input logic: Enabled during no current application), and bit 5 to 0 (near-home position input logic: Enabled during current application) so that the object stops when the home position dog turns off. In this setting, the home-position search function can be used.

(3) Connect the home position switch to the near-home position input, and connect nothing to the home position input. Set bit 4 of the control code to 0 (home position input logic: Enabled during a no-current application), and bit 5 to 0 (near-home position input logic: Enabled during current application) so that the object starts to decelerate when the home position switch is turned on, and stops when the speed reaches the startup speed. There is no sensor in the stop position; however, the object can stop at the same position every time because there are no variations in the deceleration time. The home-position search function can also be used with this setting.

Is it possible to read a program from an FP0 unit in use and write it in another FP0 unit by only using FPWIN GR and the dedicated cable? Is there any other way?

If you have FPWIN GR and an AFC8503 cable, the program can be read from FP0. (Note that if a password is set, the program cannot be read without entering the password.) The read program can be written in another FP0 unit as is. Of course, it can also be saved on a hard disk.

The other way is to use FP Memory Loader (part No. AFP8670, or AFP8671). Connect it to the TOOL port, set it to download, and then press the button to read the program. The read program is saved in F-ROM of the FP Memory Loader. Therefore, it will never be erased. Connect it to the TOOL port of another PLC, set it to upload, and then press the button to complete writing. Since reading/writing with this tool does not require a PC, it is suitable for on-site operation.

WhatÃÂâÃÂ?ÃÂ?s the difference between FL (file register) and DT (data register)?

Their purposes of use are the same, but the storage areas are different. The file registers(FL) are in the program area, and the part that is not used for programs can be allocated as data memory(DT). Therefore, the FL area changes depending on the program area size settings. On the other hand, the data registers use the operation memory area.

When the I/O points of FP2-XY64D2 are allocated, will the output points be Y30 to Y4F if the input points are X10 to X2F? Can Y numbers be allocated first instead?

For I/O mixed units, the input numbers are allocated first, and then the output numbers are allocated without exception. Therefore, you canÃÂâÃÂ?ÃÂ?t set the Y numbers first.

The auto-tuning progress indication repeats 0->1->0->1, and the proportional gain or derivative time cannot be set. WhatÃÂâÃÂ?ÃÂ?s the problem? Since the regular temperature control is functioning correctly, I believe that there are no problems with the connection.

It is possible that the operation data area value used in the parameter table has been rewritten by another program. Check if the 31-word data registers are used by another program. The F355 (PID) instruction can be used in only one section of the entire program. Do not include it in more than one section. Otherwise, correct control will be impossible. If there are multiple execution conditions, use the OR instruction or others to activate the F355 instruction.

Are there internal relays that can check if each process of the FP0 step ladder is executed?

The bits of special registers from DT9060 to DT9067 are turned on during the operation of each process. Therefore, for example, if you execute [F0, DT9060, WR10] to replace the bit information of each process operation in DT9060 with operations of the internal relays (R100 onwards), you can check execution of each process based on the internal relay operations.

FP0-T32CT has a built-in rechageable battery. Does it have a battery exhaustion alarm function?

No, it doesnÃÂâÃÂ?ÃÂ?t have a battery exhaustion alarm function. The rechageable battery is only for backup purposes. We recommend that you write data that must not be erased in the F-ROM area using the P13 instruction.

Which is better to create a relay sequence program for FP0, FPWIN GR or FPWIN PRO?

We recommend FPWIN GR to create relay sequence programs. It is compatible with the earlier software NPST-GR.

FPWIN PRO is program editing tool software based on the IEC61131 European standard. It supports ST, a PASCAL like language, SFC, a language that can be structured, and other high-level languages. Therefore, this software is suitable for reusing programs by structuring them. However, it cannot read programs from FP0, and the source files must be managed. So, use FPWIN GR unless you need these FPWIN PRO functions. Note that the FPWIN GR and FPWIN PRO programs are not compatible.

How do I connect GT30 to FP??

Connect the COM port of GT30 and the TOOL port of FP? using an AIGT8192 cable. Use the TOOL port of GT30 for screen creation. The ÃÂâÃÂ?ÃÂ?ThroughÃÂâÃÂ?ÃÂàfunction allows you to operate FP? programming and monitor communications through the TOOL port of GT30.

When I change the device by going to Edit > Change Device, the comments sometimes remain and sometimes donÃÂâÃÂ?ÃÂ?t depending on the combination of the change method [Interchange (Source<==>Destination) or Overwrite (Source==>Destination)] and whether or not the I/O comments should be changed. How do the devices change depending on the combination?

(1) Device: Interchange (Source<==>Destination) I/O comments: Change

The devices interchange their positions on the ladder, but their comments remain at the original position on the ladder. So, each combination of device and comment also changes.

(2) Device: Interchange (Source<==>Destination) I/O comments: Not change

The devices interchange their positions on the ladder together with their comments. So, each combination of device and comment does not change.

The devices interchange their positions on the ladder together with their comments. So, each combination of device and comment does not change.

(3) Device: Overwrite (Source==>Destination) I/O comments: Change

The source device will be overwritten with the target device, and the source deviceÃÂâÃÂ?ÃÂ?s comment will be attached to the target device. The source deviceÃÂâÃÂ?ÃÂ?s comment will be deleted.

The source device will be overwritten with the target device, and the source deviceÃÂâÃÂ?ÃÂ?s comment will be attached to the target device. The source deviceÃÂâÃÂ?ÃÂ?s comment will be deleted.

(4) Device: Overwrite (Source==>destination) I/O comments: Not change

The source device will be overwritten with the target device together with its comment. The source deviceÃÂâÃÂ?ÃÂ?s comment will also remain.

The source device will be overwritten with the target device together with its comment. The source deviceÃÂâÃÂ?ÃÂ?s comment will also remain.

(1) and (2): If the specified ranges of the source and target devices are overlapped, the interchange is impossible.

(3) and (4): Even if the specified ranges of the source and target devices are overlapped, the overwrite operation will be executed (although a warning message will appear).

(3) and (4): Even if the specified ranges of the source and target devices are overlapped, the overwrite operation will be executed (although a warning message will appear).

For example, when you need the source deviceÃÂâÃÂ?ÃÂ?s comment to remain and to be attached to the target device, you need to execute overwrite method (4) above, and then copy and paste the source deviceÃÂâÃÂ?ÃÂ?s comment to the target device using the batch I/O editing function.

How long is the life of the backup battery for FP1?

For the standard type: 53,000 hours For C type (with the RS232C port): 27,000 hours

Does the FP1-C40 indicate anything when the battery is exhausted?

The ERROR indication LED is turned on. The special internal relays R9005 and R9006 are also turned on. We recommend that you output the signal to a lamp or a buzzer using these relays. Note that the ERROR indication LED does not turn on if you disable Alarm battery error at No.4 in PLC Configuration.

Can a programmable console be used for FP10SH?

Programmer II can be conditionally used. Use AFP6523 cable for connection.

Generally, the 16 output points are required to display values using a four-digit digital display (BCD type). But is there any way to use only eight output points?

It is available by using the dynamic output method. With this method, displaying four-digit values requires only eight output points, and displaying eight-digit values requires only 12 output points.

Refer to the attached sample programs.

Can the F-ROM writing instruction (P13) be used for the standard type?

Yes, it can be used.

How do I establish both a PLC link and general-purpose communications using FP??

Use the newly released communication cassette AFPG806. This cassette allows a single unit to support RS232C(general-purpose communications) and RS485(PLC link) .

If a communication error occurs during W-link communications, what will happen to the link relay or link data? If a communication error occurs during F-link, what will happen to the output?

In the case of a communication error during W-link, both the link relay and link data will hold their last status. In the case of a communication error during F-link, the slave station output will generally be turned off. However, if you turn on DIP switch No. 3, the last status can be held.

When replacing FP1-C40 and an expansion unit (eight output points) with FP0, can I use the FP1 programs for FP0 as they are?

You need to convert the I/O addresses.

In addition, if you use instructions dedicated to FP1, you need to change the programs. (Change F162 and F163 to F166 and F167. Add required programs to F164 and F165.)

FPWIN has a function for the batch conversion of I/O addresses.

Can the FP2 multi-wire link unit be used as either a master or slave station? (I need functions equivalent to those of the FP3 slave unit.)

Use as a slave station is impossible. You can use the FP3 slave unit for FP2multi-wire link unit(MEWNET-F mode).

Can S-LINK be connected to an FP3 slave unit?

No, it canÃÂâÃÂ?ÃÂ?t.

GT30 made a general-purpose serial communication setup is connected to the COM port of FP2. However, they donÃÂâÃÂ?ÃÂ?t communicate. There are no problems in either the cable connection or electric continuity.

If the target PLC of GT30 is set to ÃÂâÃÂ?ÃÂ?general-purpose serial communicationÃÂâÃÂ?ÃÂÃÂ,communications with FP2 are impossible. In this case, go to File > Utility > Convert PLC Model, and select Matsushita MEWNET-FP Series.

Do I need to replace the battery to back up the user programs or data of FP0 C32T?

With regard to this model, all user programs, system registers, and data set to the hold type are saved in F-ROM. If you need to hold the non-hold type data, write it to F-ROM using the P13 (write) instruction and read it from F-ROM using the F12 (read) instruction.

FP0 T32T has a built-in Rechageable battery. This type can hold data in case of a power failure without using the P13 and F12 instructions.

An error occurred when I tried to write data to an IC card (F-ROM) inserted in FP10SH using a program. Why?

Since F-ROM is a read-only memory card, data writing by a program is impossible. Data writing is only possible with "Edit Data Resister".

If you need to write data by using a program, use the S-RAM IC memory card (part No.: AIC31000).

Which cable should I use to connect an NEC PC98 series computer to FP10SH?

Since the serial port of your PC is the 25-pin D-Sub type, use AFB85813.

FP1: PROG and ERROR indicators lit up. Has the battery been depleted?

If the mode switch returns to PROG mode even when you turn it to RUN mode, it is possible that the user program has already crashed due to battery depletion.

Purchase an AFP1801 battery , and replace the depleted battery with the new one. Then set the user program again.

IÃÂâÃÂ?ÃÂ?m using ch1 to ch6 of the FP2 A/D unit for current input. When increasing the current input to channels other than, for example, ch1, the reading of ch1 also increases accordingly. How do I prevent this?

The common pins of the input channels of the FP2 A/D unit are connected internally. Therefore, they may be affected by a change in the other channel.

With this unit, the voltage input is more stable than the current input. If the converted values with the current input fluctuate, we recommend that you adopt the voltage input.

Change the connection as shown in the attached file to adopt the voltage input without changing the settings or programs. (Digital conversion of the input range from 1 to 5 V)

Tell me the data hold area of FP0.

C10/C14/C15: Four counters from C140 to C143; 32 internal relays from R610-R62F; and eight words of data registers from DT1652 to DT1659.

C32/SL1: 16 counters from C128 to C143; 128 internal relays from R550 to R62F; and 32 words of data registers from DT6112 to DT6143.

T32: Since it has a built-in secondary battery, all points can be set to the data hold area.

I need to use a flat cable for connecting the FP? 64-point I/O units. Which connectors should I order?

Purchase AFP2802 (a set of two connectors with a strain relief).

What precautions must be taken for using the data backup battery for FP??

The backup battery does not come with the FP? unit. If you need it, purchase it separately. The part number is AFPG804.This battery is used for holding data in the memory in the event of a power failure, and operating the calendar timer. The battery life is approx. 220 days under no energization. Replace it approx. once a year.

Connect a new battery within 2 minutes after removal of the old one for replacement.

WhatÃÂâÃÂ?ÃÂ?s the part number for ordering the CR2450 battery for backing up PLCs?

The part number is AFC8801. It is for a battery for the FP2 CPU unit.

Seven PLC units are connected in the MEWNET-H link system. I set the system so that when a change is made to the file register (FL) of the first to the sixth units, the seventh PLC unit externally outputs the data of the changed FL. However, all are turned OFF. When I checked the error history by using MEWNET-H setting software, three out of the seven units showed an ÃÂâÃÂ?ÃÂ?undefined errorÃÂâÃÂ?ÃÂÃÂ. Why does this error occur? When this error occurs, does it have any other effects?

The undefined error occurs in the case of a momentary power interruption, contact failure of the coaxial connector, noise, and other problems (the cause cannot be identified). Even if this error occurs, it is ignored, and FL clearing or other operations will not be executed. We recommend that you check for differences between those conditions before and after the error occurred, such as changes in the coaxial cable processing or installation of a noise source near the units.

How do I hold data in the FP-e data register in case of a power failure?

FPWIN GR has an FP-e system register setting section where the data hold area of the data register (DT) can be set. However, this setting section is only for the calendar timer type (AFPE224305 and AFPE214325).

Therefore, never set the data hold area for the other types. Otherwise, every time the unit is powered on, out-of-control values may be recorded in the data register, causing unexpected operations. Nevertheless, if you must hold data in the data register of the other types, follow the following procedures:

(1) Write a program that will write the required data in the built-in F-ROM using the P13 instruction before power-off, automatically execute the F12 instruction using the initial pulse relay at the time of power-on, and read the data into the original data register.

(2) For automatic detection of the power-off state, use an AC power type mechanical relay, and make a circuit and a program so that the P13 instruction will be executed upon detection of the moment when the B-contact of the relay is opened.

(2) For automatic detection of the power-off state, use an AC power type mechanical relay, and make a circuit and a program so that the P13 instruction will be executed upon detection of the moment when the B-contact of the relay is opened.

Avoid writing a program that executes the P13 instruction at every scan using an always-on relay because the F-ROM writing is limited to approx. 100,000 operations.

When connecting GT30 touch panel to the TOOL port of FP10SH, how do I achieve a communication speed of 115.2 kbps? The DIP switch for setting the communication speed of the CPU unit can only switch between 19,200 bps and 9,600 bps.

Set the communication speed setting DIP switch of the FP10SH CPU unit to 19,200 bps (turn OFF No. 1). Then open FPWIN GR programming software, go to Option > PLC Configuration > COM Port > No. 414 TOOL Port Baudrate, and select 115,200 bps. Upload this setting to FP10SH to complete.

When connecting GT30 to FP0, error 61 is indicated. Why?

The error occurs when you specify a device that cannot be used by FP0 (e.g. contacts and data registers) as a screen data part of GT30. Check the device setting details of the registered parts and change them to devices that can be used by FP0.

GT30: Can I switch screens by using both the function switch and programmable controller?

You can switch the screens using the function switch by directly designating a screen number regardless of the controller status. You can also switch the screens from the controller by writing the screen number data in DT0. However, if you use both methods, there will be a difference between the screen switching data in DT0 and the currently displayed screen data in DT2, and screen switching by the controller may be impossible. In such cases, set the screen switching data in DT0, and then set and reset the forced screen switching flag (internal relay RE).

What is the Molex part number of the AFP0805 optional Molex connector crimping tool for FP0?

Molex 57189-5000

APL1634 has been discontinued. What is the substitute product?

Purchase the FP0 power supply unit AFP0634. Since it is a DIN-rail mount type, prepare a DIN rail. If you donÃÂâÃÂ?ÃÂ?t have a DIN rail, we also have an optional dedicated mounting plate (AFP0803).

I upgraded FPWIN GR to Ver. 2 successfully with the upgrade version, but Ver. 1.1 still remains. May I uninstall it since it is no longer necessary?

Yes, you can uninstall it. But make sure to leave the shared files installed during the uninstallation operation.

I tried to upgrade FPWIN GR for FP-e. But I couldnÃÂâÃÂ?ÃÂ?t uninstall the previous version from some PCs. How do I solve this?

The CD-ROM of FPWIN GR Ver. 2 includes a file named ÃÂâÃÂ?ÃÂ?setup uninstallÃÂâÃÂ?ÃÂÃÂ. Go to Start, Run, type this file name, and press OK to uninstall the previous version.

Regarding FP-e, I need to prevent the current screen from jumping to another even when the mode switch is pressed. For example, when I want to use only normal screen 1, what setting is required?

Execute the screen display switching instruction (F181) using R9010 always-ON relay in order to keep the designated screen always displayed.

IÃÂâÃÂ?ÃÂ?m using a combination of FP? (FPG-C32T2) and the communication cassette (FPG-COM1) for the FS232C transfer. However, the hardware flow control of RS-CS doesnÃÂâÃÂ?ÃÂ?t work well. Even when I directly monitor the terminals, no changes were found. I must get the FP? flow control working so that I can send large volumes of data. How do I stop the transmission request (RS: LOW)?

Use the SYS1 instruction, which allows you to control the transmission request, for RS control of the communication cassette (FPG-COM1).

RTS1 disables communications, and RTS0 enables communications. For details, refer to the Programming Manual.

Which instruction should I use to convert BCD data to decimal numbers for comparison?

Use the F81 instruction for conversion of four-digit BCD into decimal numbers (16 bits). Use the F83 instruction for conversion of eight-digit BCD into decimals (32 bits).

The comparison instructions apply to comparisons between decimal numbers, Use the F60 instruction for 16-bit decimal numbers, and F61 for 32-bit decimal numbers. In addition, ladder comparison instructions, such as ÃÂâÃÂ?ÃÂ?ST>ÃÂâÃÂ?ÃÂàand ÃÂâÃÂ?ÃÂ?AN<ÃÂâÃÂ?ÃÂÃÂ, which can be used as though it were contacts, are also available.

How do I connect FP3 and FPWIN GR?

Purchase the conversion adapter (AFP8550), the cable (AFP5520 or AFP5523), and a commercially available straight cable (9-pin female - 25-pin male for a DOS/V machine).

Do you have a resistance temperature detector unit for FP2?

You can use the FP2 analog input unit as an RTD unit by adjusting the input range. The thermocouple/RTD input units of FP3 and FP10SH are separated from the input units. However, the input units of FP2 and FP2SH can also serve the thermocouple/RTD input units.

IÃÂâÃÂ?ÃÂ?m now programming FP2, but I canÃÂâÃÂ?ÃÂ?t enter CT100. Why?

The system register counter number of FP2 starts from 1000 by default. Set the counter starting address to 100 by editing the system register(PLC configuration) in order to enter CT100.

Are 2-ch serial communications possible for FP0 without using the TOOL port?

Not available with FP0. For FP?, we have FPG-COM2, a 2-ch communication cassette (AFPG802). Therefore, we recommend that you use FP?.

When converting programs for FP2 to FP2SH, CT1000 was changed to TM1000. How do I restore it?

The counter number of FP2SH starts from 3000 by default. Set the counter starting address to 1000 by editing the system register(PLC configuration).

I purchased FPWIN GR Ver. 2 (Part No. AFPS10122) for FP1-C24. However, the supplied cable cannot be used. How do I solve this?

The cable supplied with AFPS10122 is for FP-X/FP0/FP?/FP-M/FP-C/FP2/FP2SH/FP-e. For FP1, you need an AFP1523 cable (3 m) or AFP15205 cable (50 cm), AFP8550 adapter, and a commercially available RS232C straight cable.

Can FP0 use FIFO-related instructions (from F115 to F117)?

No. FP-X,FP?, FP2, FP2SH, FP3, or FP10SH can use them.