Frequently Asked Questions For The ABB ACS800-U11 And ACS800-17 Drives

Q: What is a regenerative AC drive?

Q: What is a regenerative AC drive?

A: A regenerative AC drive (also known as four quadrant) is a drive with the ability to return energy (power) back to the supply line. The ACS800-U11/-17 has line side IGBT supply makes this possible and an active filter that keeps the supply a clean sinusoidal wave form. Conventional non-regenerative AC drives have a passive diode supply that cannot return energy to the supply line. The ability to return energy to the supply line allows you to save energy by regenerating the load energy to the line instead of to a braking chopper and external resistor. This eliminates the need for braking chopper, resistor hardware, and extra wiring for most regenerative drives.

Q: ACS800-17 drive has been previously available. What is the major difference between new ACS800-17 drive and old ACS800-17 drive?

A: New ACS800-17 drive is based on the new ACS800 inverter modules and includes expanded power size offerings. The previous version utilized ACS600 family power structure.

Q: What are the main improvements compared to the old ACS800-17 design?

A: The new ACS800-17 drive has many improvements as listed below:

• UL approval

• Extended power range up to 2600HP

• Reduced physical size

• UL Type 12 enclosure rating (optional)

• Additional, options similar to the ACS800-U7 and -07 are now available

Q: Why I can not find 400VAC version of ACS800-17 in the US price book?

A: US markets are primarily 480Vac and 600Vac. Because of this we generally do not offer 400Vac products. A 480Vac rated drive can be used on a 400Vac line voltage without any limitations or issues. It only requires tap change at the auxiliary control transformer. If you require a 400Vac rated drive for shipment outside of the US, please contact to ABB industrial sales for the quotation.

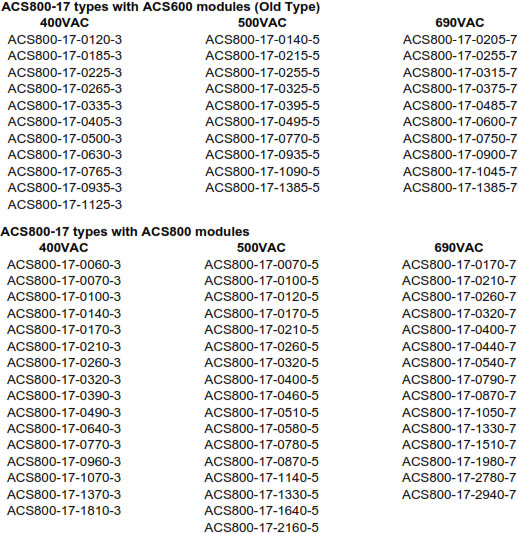

Q: How do I know if my existing ACS800-17 drive is new or old type?

A: Drive rated types are slightly different. Below you will find a list of the old and new type of the ACS800-17 drives.

Q: Can I use my existing ACS800-U2/-U4/-U7 drive spare module for the ACS800-17?

A: No, even though many of the electrical components in the both drive modules are the same, the mechanical design is different. ACS800-17 drive is using ACS800-104 modules, that cannot be exchanged with the ACS800 stand alone drive modules

Q: Is there a cabinet drive offering for 100Hp regenerative drive?

A: Yes, there is a frame R6 offering available in a cabinet enclosure for 75 to 125Hp. Contact you local sales representative for information.

Q: Is the ACS611 still available?

A: A limited stock of ACS611’s are still available. When this inventory is exhausted no further inventory will be purchased. The ACS611 is moving to classic status and is replaced by the ACS800-U11.

Q: Why does the ACS800-U11 cost more than the ACS611?

A: The ACS800-U11 is competitively priced. Generally price levels are very similar to the ACS611 except where some corrections were needed regarding to the positioning of the ACS611. The fully integrated packaging and low harmonic solution of the ACS800-U11 is the best in the market with the greatest power range offering of any regenerative wall mount AC drive.

Q: What is the type code designation of the new ACS800 regenerative drive?

A: The type code designations for the new regenerative AC drives are the ACS800-U11 and ACS800-17. The ACS800-U11 is specifically designated for the US market and includes the US conduit box with the drive and is defaulted for horse power and 60Hz configuration. The ACS800-17 requires the plus code +C129 for UL marking. This is the standard for the US market.

Q: What is the difference between the ACS800-11 and the ACS800-U11?

A: The difference is the default power configuration for 60Hz and US conduit box. The ACS800-U11 will be supported as a standard product and stocked locally. The ACS800-11 will not be stocked in the US and should not be ordered for North American delivery.

Q: Is the ACS800-U11 smaller than the ACS611?

A: Yes, in total volume the ACS800-U11 is smaller than the ACS611. In width and depth the ACS800-U11 is smaller than the ACS611, in height the ACS800-U11 is less than 1 inch taller than the ACS611.

Q: Is the ACS800-U11 available in 230Vac?

A: Yes, the ACS800-U11 is offered in a 230Vac configuration. There currently is not an offering for a 600Vac wall mounted regenerative drive. For 600Vac regenerative applications please see the ACS800-17 regenerative cabinet drive package.

Q: Is the ACS800-U11 available with NEMA Type 12 enclosure?

A: The ACS800-U11 is not available in a NEMA Type 12 enclosure (IP55). For NEMA Type 12 application requirements it is recommended to apply the ACS800-U11 in a separate enclosure rated for the level of protection needed. Please contact engineered drives, your local panel shop, or system integrator for further information.

Q: What is the basic configuration of the ACS800-17 in US?

A: The basic offering for the ACS800-17 in the US includes the required plus code +C129. This includes all US standard configuration such as UL Type1 floor standing enclosure, top entry and exit for the cabling, 115VAC internal control voltage, UL approved main switch, UL approved fuses, UL approved components, and US conduit plate,

Q: Why does the ACS800-17 drive have main contactor (up to R8i) or main air circuit breaker as a standard (nxR8i)?

A: The main contactor or circuit breaker is used as part of the pre-charging circuit of the DC bus capacitors.

Q: What options are available for the ACS800-U11 and -17?

A: All of the “common” options listed in the stand-alone drives price list are available for the ACS800-U11 and -17 product. Additional kVA specific options are also available, including 2nd environment and 1st environment filters for most power sizes.

Q: Can Nxxx type option modules be used with the ACS800-U11 and -17?

A: Yes, most legacy Nxxx type I/O extension and FieldBus option modules can be used with all ACS800 family products. The Nxxx type option modules will require a RDCO module that is standard with the ACS800-U11.

Q: What other changes are there from the ACS611 to the ACS800-U11?

A: The ACS800-U11 is a completely new design based on the ACS800 product family. The new ACS800-U11 includes:

• An extended power range up to 150Hp with the new Frame R6 offering

• An integrated LCL filter is standard in both R5 and R6 frames

• Access to the control “supply” line parameter settings

• Power loss ride through even when regenerating

Q: Why does ACS800-U11 and -17 have two control boards?

A: The regenerative AC drives have two control boards in the complete package. One control board is for the active supply unit and the other for the inverter. Only the motor side (inverter) control board is accessible from the front of the drive. The active supply control board is internal to the drive and requires no external connections. All I/O and support connectivity is through the motor control board at the front of the drive.

Q: Do I need to do any setup to the active supply unit?

A: No, the active supply does not need additional configuration to operate. All supply line side configuration is automatic, Start-up of the drive is similar to any other ACS800 standard drive. However, there are some parameters that can be set separately for the active supply unit.

Q: Can the parameters of the line controller be adjusted with the CDP312R keypad?

A: Yes, the parameters of the line side controller can be accessed by changing the node number on the CDP312R keypad.

Q: Is ACS800-U11 UL listed?

A: Yes, The ACS800-U11 has product markings for UL and CE, marking for CSA and C-tick are pending.

Q: Is ACS800-17 UL listed?

A: For US usage the drive is typically ordered with +C129 for inclusion of UL marking. If CE marking is required, the drive should be ordered without +C129. The US price list includes the +C129 plus code for UL marking.

Q: Does the fiber optic connection (RDCO) for the ACS800 product family need to be purchased separately for the ACS800-U11 /-17?

A: No, the RDCO-03 is included in all ACS800-U11/-17 drives as standard and does not need to be ordered separately. The RDCO is used to communicate between the 2 RMIO control boards included in the drive.

Q: Can the ACS800-U11 be used in common DC bus applications?

A: Yes, contact ABB Application Engineering for support in common DC bus applications for proper sizing, product mix, and application rules.

Q: Can the ACS800-U11 be flange mounted?

A; No, flange mounting is not available for the ACS800-U11

Q: Are there any special connections required for the ACS800-U11?

A: No, unlike competitive regenerative product offerings the ACS800-U11 is a complete integrated package and requires no additional interconnections. The installation of an ACS800-U11 regenerative AC drive requires the same simple connections as a conventional non-regenerative ACS800 drive.

Q: What is an LCL filter?

A: An LCL filter is a passive filter which consists of a reactor (L), a capacitor (C), and another reactor (L) arranged in a T-section configuration. Each input phase of the ACS800-U11 includes a symmetrical set of these components. The inductors are series power components that carry the full current of the drive.

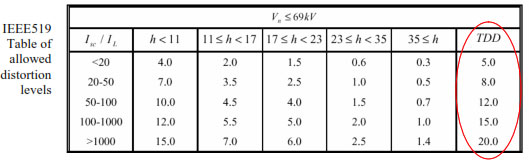

Q: Are current harmonics lower on an ACS800-U11/-17 AC drive than the current harmonics on a conventional AC drive?

A: Yes, the ACS800-U11/-17 provides exceptionally low harmonic levels because of it’s active supply unit and integrated LCL filter. The ACS800-U11/-17 AC drive meets IEEE519 requirements for current and voltage distortion with actual (TDD) distortion levels of less than 5% at the input to the drive.

Q: Can a brake chopper be installed in an ACS800-U11 drive?

A: Yes, you can optionally add a braking chopper to an ACS800-U11 drive. This must be requested at the time of ordering and requires special quoting per application. Please consult the factory for support of the braking chopper option in the ACS800- U11 AC drive.

Q: Why would I use Braking chopper in a regenerative drive?

A: For applications requiring braking even when there is incoming supply line loss, the braking chopper will provide braking down to approximately 10% motor base speed. Therefore, in applications where it is critical the load is stopped quickly even if there is power loss, a brake chopper is a good solution.

Q: Can a circuit breaker be used instead of fuses to protect the drive?

A: No, circuit breakers do not provide sufficient short circuit protection. Fast blow fuses (semiconductor fuses) are recommended for drive protection such as Bussman type JJS T-class fuses. See the drive hardware manual for recommended fuse sizing and types. For the ACS800-17 aR fuses are included and must be used as supplied.

Q: Can fuses other than Bussman be used to protect the drive?

A: Yes, see the fuse manufactures cross reference table and select the appropriate fuses based on the recommendations for the ABB hardware manual and the manufactures cross reference table. Equivalent semi-conductor type fast blow fuses are required.

Q: Why is an external UPS needed for power loss ride-through in ACS800-17?

A: In ACS800-17, the auxiliary power for the control is taken from AC supply for practical reasons. Thus, auxiliary supply needs to be secured if ride-through is required. This will be changed in future so that auxiliary power is taken from DC link to be consistent with other ACS800 stand-alone drives. When implemented, an external UPS supply will not be needed.