Full Inox Basic: Robust inductive sensors for the entry level

The Full Inox BASIC family closes the gap for applications that cannot dispense with a full-metal housing, but still need a cost-effective solution. The BASIC line combines the robustness and long life of the Full Inox family with the sensor properties of standard technology to offer a cost-effective entry into the world of the full-metal sensors.

The Full Inox BASIC family closes the gap for applications that cannot dispense with a full-metal housing, but still need a cost-effective solution. The BASIC line combines the robustness and long life of the Full Inox family with the sensor properties of standard technology to offer a cost-effective entry into the world of the full-metal sensors.

-Mechanically and chemically extremely robust

-High quality ASIC sensor

-Factor 1 on steel and aluminum

-Corrosion resistant

-IP68 and IP69K

-Excellent temperature compensation

-Vibration and shock-resistant

Advantages of the Contrinex ASIC:

-Guaranteed operating distances

-Quick installation: lower tolerance values, easy setup with or without IO-Link

-Excellent temperature compensation

-Long life especially in environments with temperature changes and vibrations

-Extended operating distances

Mobile equipment

Repairing and servicing equipment on site can be difficult and costly at best, and sometimes impossible. In these circumstances, robust, highly reliable sensors are vital for continuous operation in environments that may be challenging in the extreme. Exposure to dirt and dust, impact, vibration, seawater, corrosive chemicals and extremes of temperature and pressure are all part of a regular day’s work.

-Mechanically and chemically extremely robust

-Very long lifetime in applications subject to vibration and temperature changes

Machine building

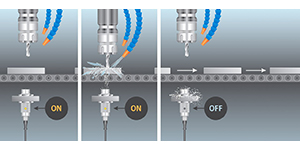

Machine tools impose harsh operating conditions on the sensors needed to control cutting, forming and joining processes that run continuously in many metalworking factories. Common hazards include cutting fluid, cooling sprays, swarf particles and electromagnetic interference, making sensor selection particularly difficult where world-class performance is essential.

-Extreme robustness

-No false switching caused by metal dust or chips

-Cost-optimized solution

Automotive manufacturing industry

Today, sensors of all types are common in automotive factories around the globe. Highly automated plants with demanding conformity requirements rely heavily on sensor technology to maintain world-class quality standards, particularly where harsh processes such as welding, metal finishing and high-temperature coating are required.

Manufacturing engineers working for automotive manufacturers and for first- and second-tier suppliers expect robust, reliable sensors that deliver accurate, repeatable results with minimal downtime.

-Cost-optimized solution for the toughest applications

-Same operating distance on steel and aluminum

-No false switching caused by metal dust or chips