Safety Product Range

Contrinex 12th Dec 2022

Safetinex products offer high-quality safeguarding solutions for both personnel and machinery. The range comprises light curtains of Type 2 or 4 according to the international standard ISO 13849. Resolution is suitable to protect hands (30 mm), fingers (14 mm) or full body (3 to 6 beams). A choice of standard or slim profile is available in various lengths up to almost 2 meters. Wireless configuration through Bluetooth is available with Extended Type 4 devices. The portfolio also comprises safety sensors with either a magnetic or RFID operating principle.

Safetinex products have been developed in compliance with the applicable international safety standards and have obtained the required product certification for use in the European Union, the United States of America and all other countries where the applicable IEC standards have been adopted. A complete range of Safetinex light curtains and access control barriers is offered for the highest safety requirements: safety category 4, PL e according to EN/ISO 13849-1, Type 4 according to IEC 61496-1 and -2. In addition, hand protection devices are available with a Type 2 safety rating (IEC 61496-1 and -2) which meet category 2, PL c according to EN/ ISO 13849-1.

Safety sensors also meet the requirements of safety category 4 according to EN/ ISO 13849-1. Their magnetic or RFID coding is rated type 4 according to EN/ISO 14119 and housings are ECOLAB certified. All Safetinex products have TÜV certification.

SAFEGUARDING FUNCTION

In all cases, the primary function of the protective device is to stop the machine before the hazardous point is reached and to prevent unintentional machine startup. This function must comply with the category of the safety-related components of the machine.

LIGHT CURTAINS

Whenever a safety system around a danger zone is necessary, the first consideration is whether or not optical protection is suitable at all. For this to be the case, it must be possible for the machine control to be electrically influenced by means of the device’s semiconductor output. Moreover, it must also be possible to instantly terminate or exit the hazardous process in every operating phase. Further, there must be no danger of injury due to heat, radiation or from materials or components ejected by the machine. If such danger exists, then either the optical system is not suitable, or the danger must be otherwise excluded by applying additional safety measures.

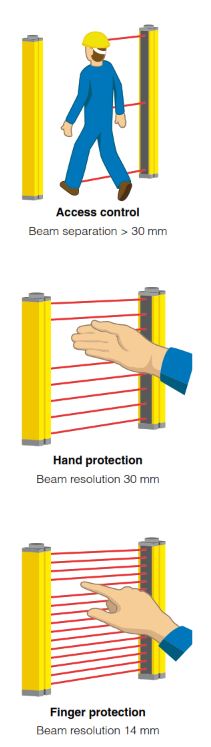

The selection of a specific safeguarding measure involves an evaluation of the hazard, in order to determine the applicable safety level and resolution of the protective device.

The resolution of the safety light curtain or access control barrier must be chosen according to the application and the required safeguarding function. It is defined as the minimum size of an object that can be reliably and safely detected at any position when placed in the protective field. The choice of a specific resolution depends on the part of the body which needs protection (finger, hand or whole body).

APPLICATION AREAS

The Safetinex YBB, YBBS and YBES ranges are best suited where finger and hand protection is required close to the hazardous area (point of operation). Depending on the application, a resolution of either 14 mm (finger protection) or 30 mm (hand protection) will be advisable. Safetinex YCA access control barriers, on the other hand, are suitable for the protection of people potentially entering a larger dangerous area.

Thanks to their Type 4, category 4, PL e safety level, Safetinex devices can be used on equipment requiring high protection reliability, such as machine tools, robots, hydraulic presses, automated stock management, weaving looms, etc.

If the result of the risk assessment allows their use, Type 2 devices (category 2, PL c) offer cost effective and safe solutions.

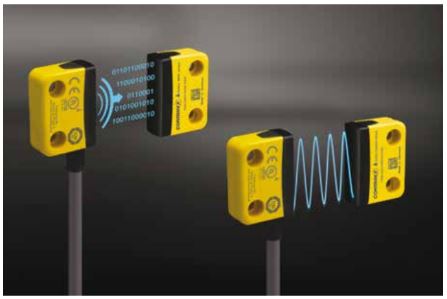

SAFETY SENSORS

For any machine requiring a fixed guard-door or cover, contactless safety sensors ensure reliable state monitoring (door open or closed). A magnetically or RFID-coded system (type 4 according to ISO 14119) makes them immune to mutual interference and highly resistant to tampering.

Sensors with magnetic coding can be mounted behind a stainless steel plate, which further reduces accessibility. Types with random or teachable RFID coding provide individual feedback and can be connected in series, allowing up to 30 sensors to connect with just one relay or controller.

For the monitoring of guard doors, hoods or covers, contactless safety sensors must be chosen with an appropriate coding technology (magnetic, RFID) to minimize the risk of tampering.

SAFEGUARDING FUNCTION

For any machine requiring a fixed guard-door or cover, Safetinex YSM and YSR contactless safety sensors provide state monitoring (door open or closed). The magnetic or RFID coding is classified as type 4 according to ISO 14119. Security level is Category 4 according to ISO 13849-1. The IP6K9K enclosure rating and ECOLAB approval make the sensors suitable for washdown applications.

YSM types with magnetic coding are suitable for simple monitoring tasks, being very economic and easy to wire. It is also possible to mount the actuator behind a stainless steel plate.

YSR types with RFID coding are suitable for more complex tasks. Since each sensor can provide individual feedback, it is possible to identify which guard-doors are open and which are closed. YSR sensors can also be connected in series, allowing up to 30 sensors to connect with just one relay or controller. YSR types are therefore particularly suitable for applications using multiple sensors, such as long packaging or assembly lines. They are not sensitive to vibration and provide self-tested OSSD signals.

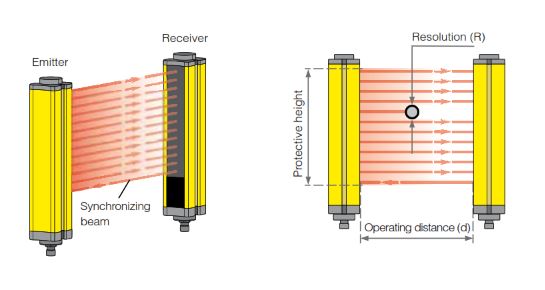

OPERATING PRINCIPLE OF LIGHT CURTAINS

Safetinex YBB, YBBS and YBES light curtains and YCA access control barriers operate with infrared beams. When the device detects a finger, a hand or a person entering the defined hazardous area, the protective equipment immediately stops the machine, or renders it harmless. When operating in manual restart mode, the reset button enabling the operator to restart the machine must be located outside the hazardous area. From there, the operator must have a full view of the hazardous area to make sure that nobody is in danger before restarting the machine.

Safetinex light curtains and access control barriers are designed to ensure protection of operators working in hazardous areas. A high reliability is achieved by implementing a fail-safe system: devices are thus permanently self-controlled. An internal failure deactivates the output signals, as would an intrusion into the protective field.

Safetinex light curtains and access control barriers are active optoelectronic protective devices (AOPDs) that include a sender and a receiver unit between which coded infrared beams are sequentially exchanged. The receiver unit is connected to a safety relay which transmits signals to the machine control system. Synchronization between the sender and receiver devices is performed optically, i.e. wired connection between the two units is not necessary.

Reception of all beams activates the two independently generated semiconductor outputs (OSSDs) of the receiver unit. The interruption of one or more beams deactivates the outputs within the response time of the AOPD. Any internal fault is detected by the device’s permanent self-control function and has the same result as an intrusion into the protective field.

AOPD DETECTION CAPABILITY

The light curtain or barrier detection capability (or resolution) is the sum of the distance between two adjacent beams and their combined diameters. The choice for a specific resolution depends on the part of the body which needs protection (finger, hand, whole body).

SELF PROTECTED OUTPUTS

Both OSSD1 and OSSD2 are self-protected and actively monitored PNP outputs. Both outputs are controlled by independent current-monitored high-side switches. Thanks to continuous monitoring, any short-circuit between an output and the power supply or ground is detected within the response time, leading to the deactivation of the other output. Similarly, a cross-circuit between the two outputs is also detected and both OS-SDs are deactivated within the specified response time. The OSSD outputs are switched off and remain in that state as long as the fault remains.

OPERATING PRINCIPLE OF SAFETY SENSORS

Safetinex YSM and YSR safety sensors comprise two parts: a main module and an actuator. They communicate with a contactless system of either magnetic or RFID coding. When the system detects that a guard door, hood or cover is open, the protective equipment immediately stops the machine, or renders it harmless.

YSM magnetic safety sensors use a coded magnet as an actuator and two reed contacts to open or close communication. Unlike light curtains, these sensors do not have OSSD outputs with self-check. They act simply as contactors that open or close depending on the presence or absence of a magnet. It is therefore necessary to apply power to the reed contacts.

YSR RFID safety sensors use an RFID tag as an actuator and a read and write module (RWM) as a contactor. These sensors have self-checking OSSD outputs, similar to light curtains. They are therefore connected in the same way as light curtains to a relay or controller. The RFID tag can be universally and randomly coded or can be teachable, which means the user pairs it with an RWM at first use to create a unique combination.

12th Dec 2022