The Application of Inductive Proximity Switches with Analog Output

Contrinex 12th Dec 2022

General application advice

In general, the same application rules as for the well-known inductive switching devices apply. However, there are, in addition, a number of extra features, which are discussed in the application report "New Inductive Proximity Switch with Analog Output".

The following application examples have all been taken from practice. Due to space availability, only a selected few are described here, the possibilities being virtually unlimited.

Application examples

1. Several switching points with a single proximity switch

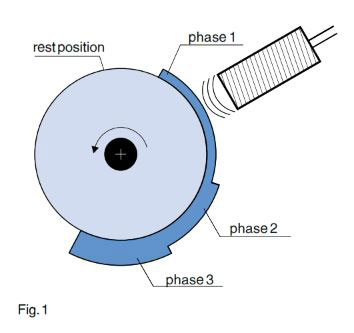

One often comes across the case that, during the movement of the target to be detected, a particular action should not be triggered at just one position. More often, relevant specific actions should take place at various positions. Thus, in a program switching station, the task can be resolved using a single disk and a single analog device (Fig. 1), instead of several disk cams and an equal number of normal switches. Evaluation in the case of a PLC application is carried out via a PLC input module with analog inputs (e.g. Siemens S5, type 6ES5 464-8MC11). For current PLCs, these modules are available at reasonable prices. Alternatively, appropriate signal evaluation devices, available from various suppliers, can be used.

2. Conversion of a linear movement into an electrical signal

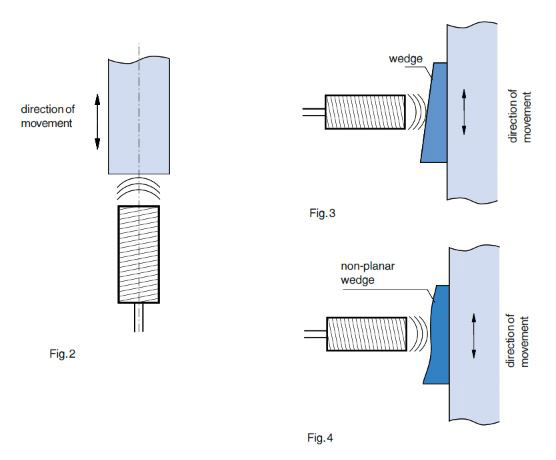

In the simplest case, a linear movement can be directly converted, as shown in Fig. 2. In this case, it only has to be ensured that the device is not physically touched. In practice however, the sensing range of the devices is often not enough for such a direct detection. However, using a wedge-shaped intermediate piece, it can be modified at will (Fig. 3). Moreover, interesting possibilities arise when this piece is non-planar. For instance in this way, linearization of the transfer function can be achieved (Fig. 4).

3. Conversion of a rotational movement into an electrical signal

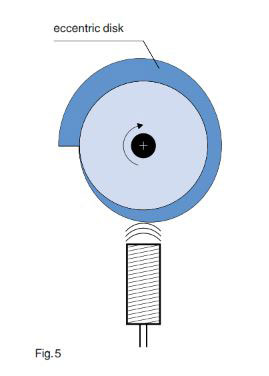

Delivery of a rotational movement or an angle to the analog device can be made by using an eccentric disk (Fig. 5). As in example no. 2, by a suitable choice of the disk form, the angle range can be modified within wide limits, and I or a linearization of the transfer function can be effected in this case too.

4. Start-up adjustment

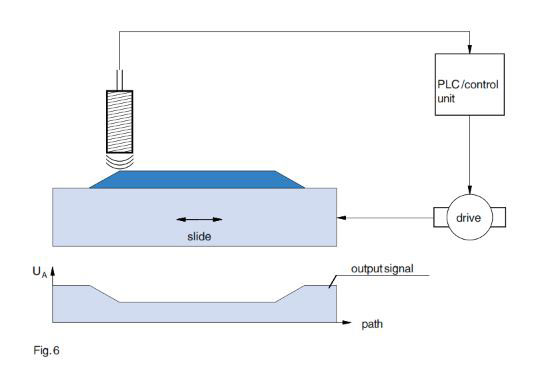

The classical procedure of motion control consists of simply switching off the drive after passing over an end point (detected for instance by means of a binary proximity switch). The mechanical endpoint position is however quite vague as a result of uncontrolled runout. By using a proximity "switch" with analog output, together with a PLC for instance, it is possible to carry out high-precision startup adjustment at negligible cost (Fig. 6).

5. Elevator start-up adjustment

An interesting case of start-up adjustment is found in the field of elevators. A conventional elevator generally switches to crawling shortly before reaching its destination, and then stops abruptly without overshooting to any great extent. This is certainly very simple from the technical viewpoint, but there are two drawbacks. Firstly, the crawling phase prolongs the total traveling time, and secondly, despite crawling, the accuracy of the end position is both limited as well as load dependent. By using an analog inductive proximity switch as a transmitter for detecting the cabin position, combined with a startup adjustment (analogous to Fig. 6), these disadvantages are elegantly resolved, with no appreciable increase in the sensor cost. The requirement for an adjustable drive creates an additional expense, but today, these no longer cost the earth.

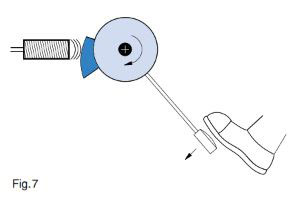

6. Detecting the pedal position in vehicles

The pedal positions in modern vehicles are required as information sources for numerous processes. Their detection requires sensing devices that convert a path or angle into an electrical quantity, which can then be fed to the control system. In the simplest case, these converters consist of a potentiometer; in addition, magnetic field semiconductors are used. Moreover, the use of displacement sensors, which work according to the differential transformer principle, is conceivable.

However, there are applications where previously no satisfactory solution had been found, i.e. construction equipment. Here, a high level of vibration is combined with the worst possible environmental conditions, such as dirt, extreme operating temperatures and humidity. Moreover, permanent magnets are not well viewed, since they collect metal parts and shavings. Unacceptable reliability problems are the inevitable result.

Analog inductive proximity switches meet all the above requirements to a great extent, and moreover, at a favorable cost. Constructional realization is very simple,

as Fig. 7 shows.

7. Non-contact potentiometer

What has been said above concerning vehicle pedal position is of course also valid for other applications where mechanical values have to be converted into electrical ones. The use of a proximity switch as a potentiometer is not obvious at first sight, but however it permits a constructively simple solution to the problem, e.g. following Fig. 5. Multiturn potentiometers can also be simply realized (with spindles).

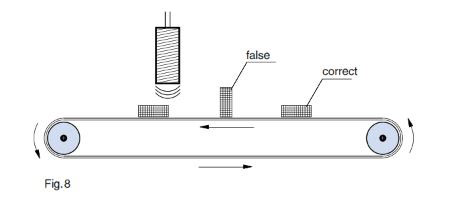

8. Parts control

Monitoring of the correct position of parts on conveyor belts is a classic application for photoelectric proximity switches, above all in combination with optical fibers. In the case of metallic parts, analog inductive proximity switches offer an interesting alternative, particularly as far as sensitivity to dirt and costs are concerned. An example is shown in Fig. 8.

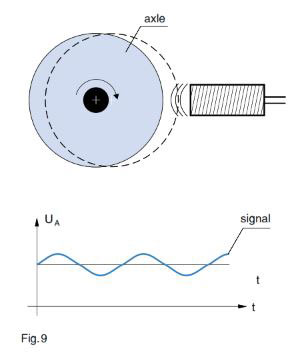

9. Monitoring of axle concentricity

In the concept of preventive maintenance, the monitoring of axle concentricity plays an important role. During the course of time, concentricity can deteriorate in an unpredictable fashion, e.g. due to bearing wear, leading to unexpected and often catastrophic breakdowns with costly repairs and downtime. Continuous concentricity means of twisting the device in the thread. This certainly involves supplementary labor, but at least it does not give rise to problems with the original equipment. The situation is completely different during field replacement. Here, the manufacturer is at the mercy of the qualifications and competence of his customer's maintenance personnel. For this application, the analog inductive proximity switch offers a relatively lowcost and interesting alternative. The reasoning behind this is that during installation, the proximity switch is adjusted only approximately, e.g. by eye using a mark or label. Next, an initialization cycle, which is anyway in most cases already available in the software, is started. It merely has to be extended with a suitable, lowcost module. In the course of initialization, the control system brings the machine part monitoring allows immediate information concerning the state of the bearings. It is true that there have been efficient devices on the market for some time for this purpose but, however, their price has hindered wide application. It is quite the opposite with analog inductive proximity switches, their price being only a fraction of that of conventional systems, and their use and signal evaluation are child's play (Fig. 9). Their capacity, on the other hand, is exceptionally high, and can measure up to systems many times more expensive. The definition and short-term repeat accuracy reach such high values (in the region of e 0.1 µm) that, as a rule, they cannot be measured with normal workshop equipment. Attention must only be paid to ensure that the electronic analyzer can keep pace!

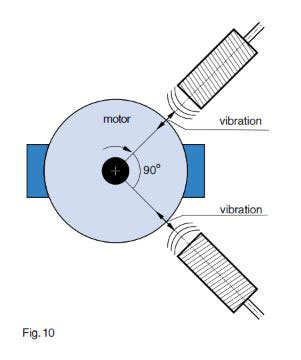

10. Vibration monitoring

Vibration can also be an indication of a machine's condition. Monitoring of its amplitude over a period of time makes preventive maintenance possible, and helps eliminate unexpected and often catastrophic breakdowns with costly repairs and downtime. In this case also, a proximity "switch" with analog output, in combination with a PLC, frequently already installed, offers a simple, cost-effective and, in many cases, adequate solution (Fig. 10). Monitoring can take place axially, biaxially or triaxially, one proximity switch being necessary for each axle. In this application, attention must be paid to the device's upper frequency limit.

11. Automatic adjustment of the switching point (Teach-in)

In many cases, the switching point of proximity switches must be maintained with extreme accuracy, and for this reason, it is mechanically adjusted during installation by means of twisting the device in the thread. This certainly involves supplementary labor, but at least it does not give rise to problems with the original equipment. The situation is completely different during field replacement. Here, the manufacturer is at the mercy of the qualifications and competence of his customer's maintenance personnel.

For this application, the analog inductive proximity switch offers a relatively low-cost and interesting alternative. The reasoning behind this is that during installation, the proximity switch is adjusted only approximately, e.g. by eye using a mark or label. Next, an initialization cycle, which is anyway in most cases already available in the software, is started. It merely has to be extended with a suitable, low-cost module. In the course of initialization, the control system brings the machine part to be detected to the exact point where the corresponding proximity switch must react. The signal at the output of the analog inductive proximity switch is now read by the PLC, and digitally stored as switching point information in the memory. This value will only be overwritten during an eventual future initialization cycle. In such a cycle, any number of proximity switches can be installed accurately, speedily and independently of the skill and reliability of the maintenance personnel.

12. Automatic correction of specimen scatter

Like all components, analog inductive proximity switches are inevitably subject to specimen scatter, whose value given in the manufacturer's data sheets is for the most part only rudimentary. CONTRINEX data sheets, however, indicate this value at three points on the curve, which nevertheless does not alter the fact that scatter can be too high for certain applications. This means that manual adjustment is necessary, which is a considerable disadvantage when fitting exchange parts in the field. Here, the procedure described in the previous paragraph can be used, and the problem thus elegantly resolved.

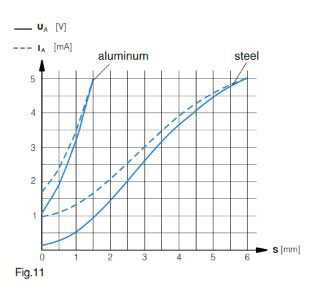

13. Electronic linearization of the response curve

Inductive technology produces a rough curve (for instance as in Fig. 11), which is not particularly linear, especially at the ends of the range. Certainly, the proximity switch manufacturer could build an additional linearizing circuit into his device, but this would, however, make it larger and more expensive. This need not be the case of electronically controlled applications. On the contrary, the curve should be digitally linearized. To achieve this, a procedure that inserts the

device's transfer function into the PLC memory during an initialization cycle is used. Instead of a single switching point as in example number 11, the whole response curve of the device, with an application-specific resolution, i.e. with sufficient numbers and positions of measuring points, is memorized during the initialization cycle. After digitalization of the measured values, the ratio between the measured and ideally expected value is calculated for each measuring point, and stored in the form of a correction table in the PLC. During operation, this table is then interposed between the values registered and the further signal treatment.

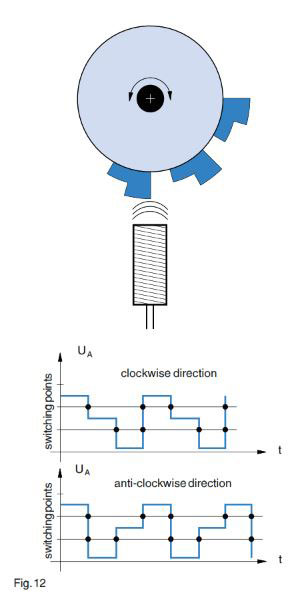

14. Identification of direction of rotation with only one proximity switch

By a suitable arrangement of the toothed or perforated disk (see also the application report "Inductive Proximity Switches as Encoders"), identification of the direction of rotation is possible with only one, in this case analog, proximity switch. For this, there are a number of possibilities, of which one example is shown in Fig. 12. At the electronic analyzer, three switching points are set, two of which must lie in the area of the teeth surfaces and one outside. From the sequence in which they move past, the direction of rotation of the toothed or perforated disk can be derived. It goes without saying that the rotational speed can thus be measured at the same time.

Summary

With the series of analog inductive proximity switches with large sensing ranges introduced by CONTRINEX, an abundance of technically interesting and economically advantageous possibilities for converting mechanical quantities into electrical ones have become available to constructors. The devices combine the well-known advantages of tried and tested inductive proximity switches with those of mechanically susceptible potentiometers, magnetic field sensors with permanent magnets and far more complex length measuring systems.

12th Dec 2022